Imagine a gleaming glass curtain wall on a high-rise in a bustling city, alive with dynamic LED displays that shift colors through rainstorms and dusty winds. These setups don’t just catch eyes—they endure. For project managers handling large-scale architectural projects, picking the right fixtures means decoding those IP ratings stamped on specs sheets. Get it wrong, and moisture creeps in, shortening the glow from years to months. IP ratings in architectural LED lighting spell out how well a product stands up to solids and liquids, but real protection goes beyond numbers. It’s about fixtures that thrive in harsh spots like traffic hubs or enterprise exhibit halls, where failure isn’t an option.

This guide breaks down what those codes really mean for outdoor installations. We’ll dig into how they guard against everyday threats, spotlighting designs that deliver on promises. Drawing from hands-on experience in urban landscapes, the aim is to help buyers spot fixtures that last, cutting down on callbacks and boosting project success. In a market where waterproof LED lights face constant exposure, grasping IP levels ensures your investment shines bright, rain or shine.

The Basics of IP Ratings

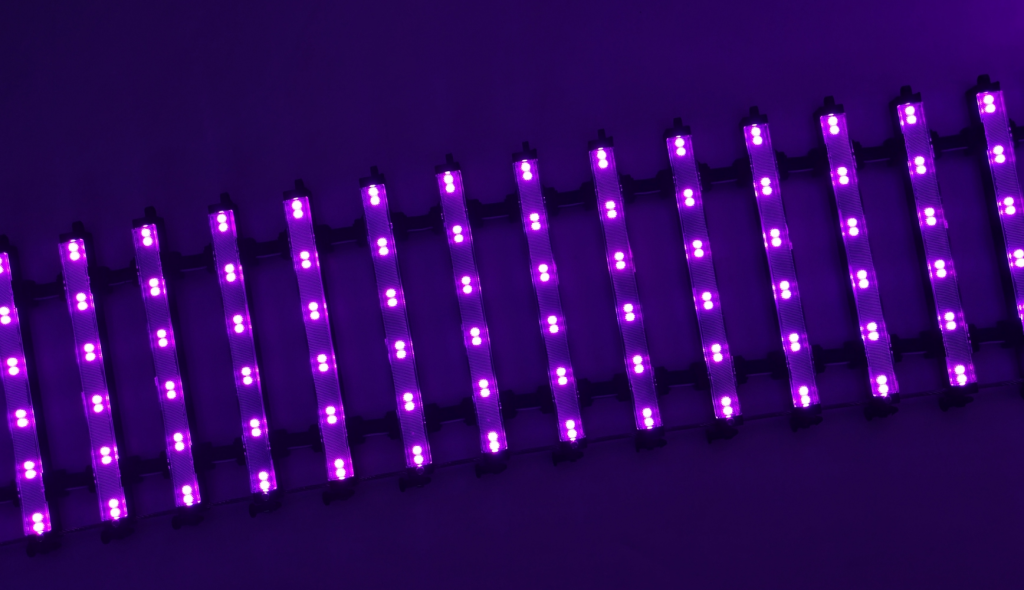

IP stands for Ingress Protection, a standard set by the International Electrotechnical Commission to rate how enclosures block dust and water. The code has two digits: the first tackles solids, from fingers to fine particles; the second deals with liquids, from drips to full submersion. For architectural LED lighting, these aren’t abstract—they dictate if a grid screen on a mall facade survives a downpour or if point lights in a subway station handle humid air without flickering out.

Take the first digit. A 6 means total dust-tight seal, crucial for spots like construction sites where particles swirl. The second digit ramps up: 5 resists water jets, good for occasional sprays; 7 handles temporary immersion, ideal for flood-prone areas. Research from the Journal of Light & Visual Environment (2017) shows that fixtures with IP65 or higher cut failure rates by 40% in wet conditions, as seals prevent corrosion that dims output over time. In practice, lower ratings might work indoors, but outdoors, anything below IP65 invites trouble, like short circuits from splashes.

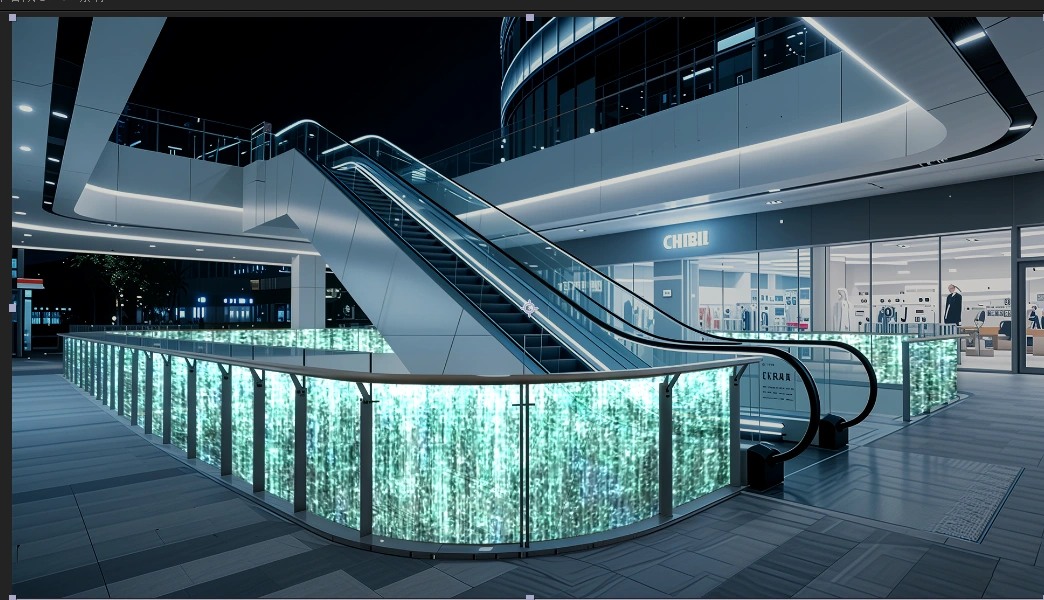

Understanding these helps procurement teams match ratings to needs. For glass guardrails in cultural tourism spots, IP67 in architectural LED point lights keeps internals dry during monsoons. It’s not just specs—it’s peace of mind when lights must run 24/7 without a hitch.

IP Applications in Architectural LED Lighting

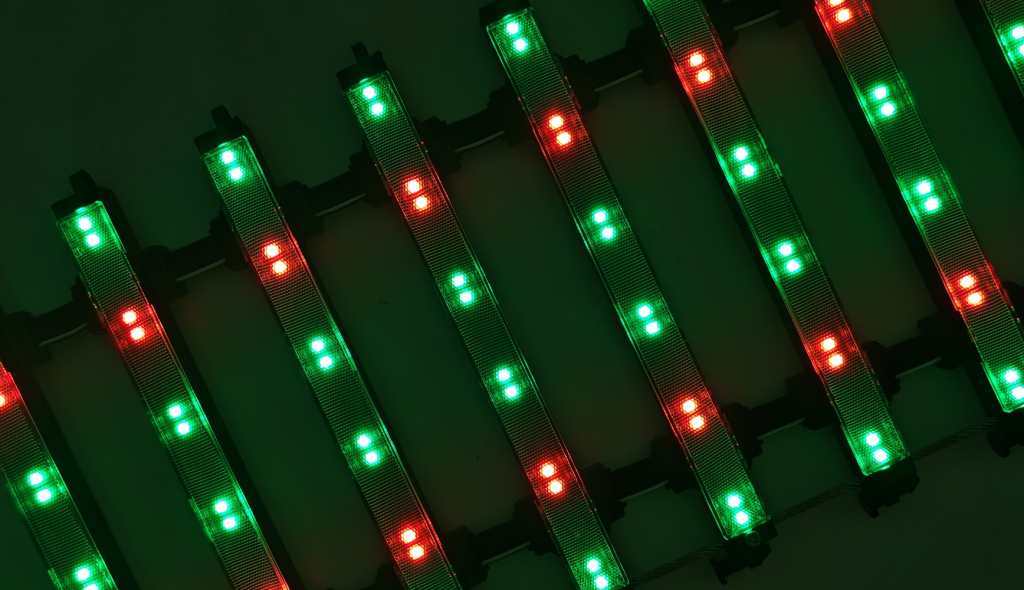

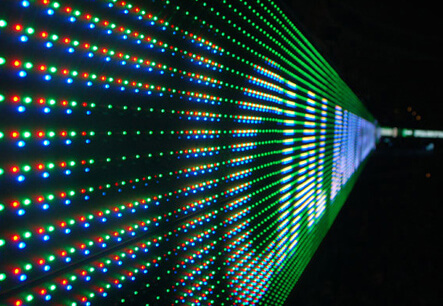

In architectural setups, IP ratings shape how LEDs perform in real-world chaos. Compare IP65 and IP67: the former shrugs off hose-downs, fitting for semi-exposed spots like indoor partitions; the latter dives deeper, surviving 30 minutes under a meter of water, perfect for outdoor glass curtain walls battered by storms. Sealed environment LED thermal control ties in here too, as higher IPs often mean tighter builds that demand smart heat venting to avoid decay.

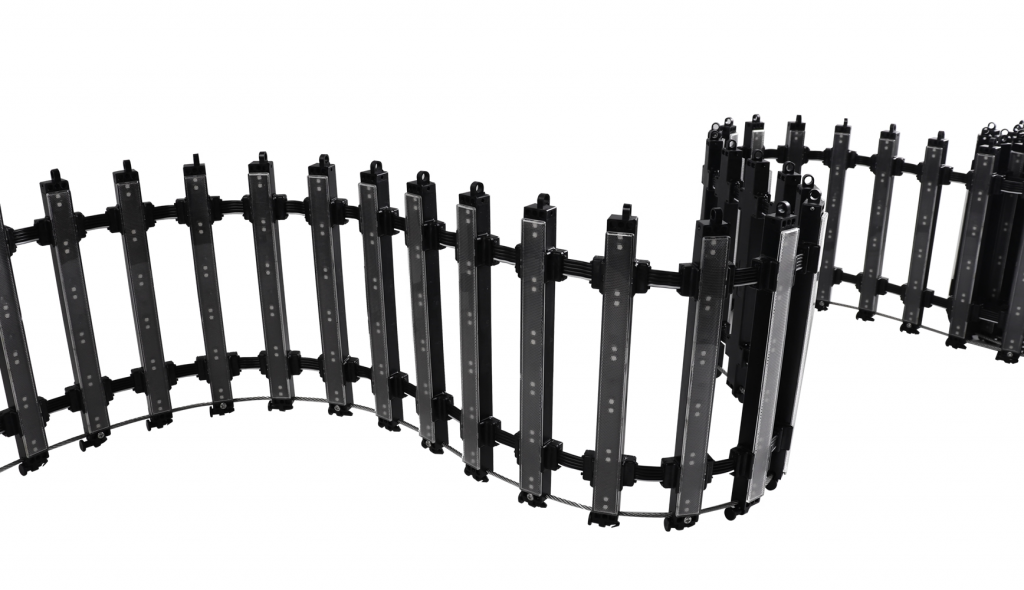

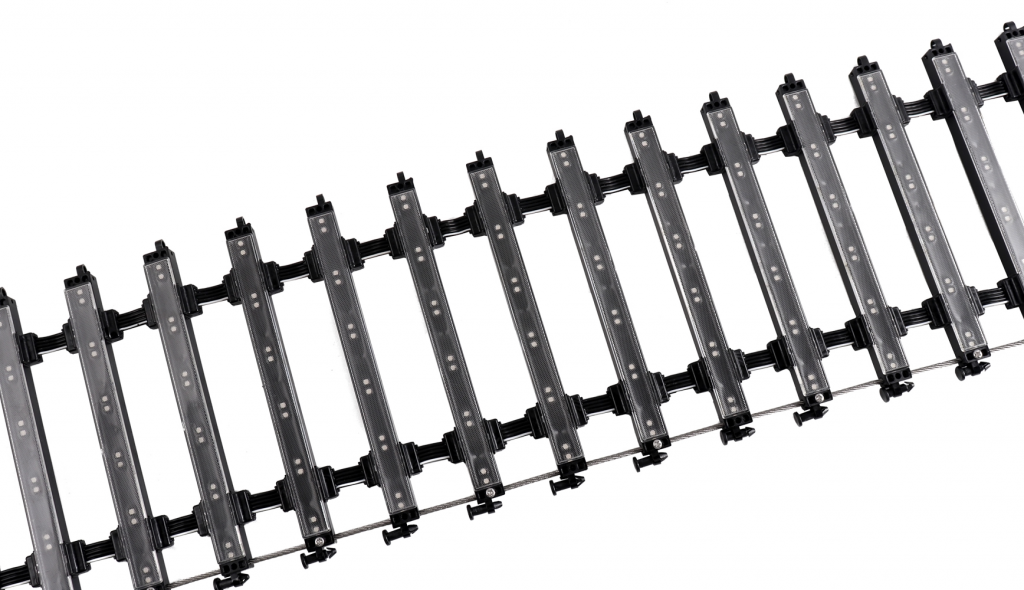

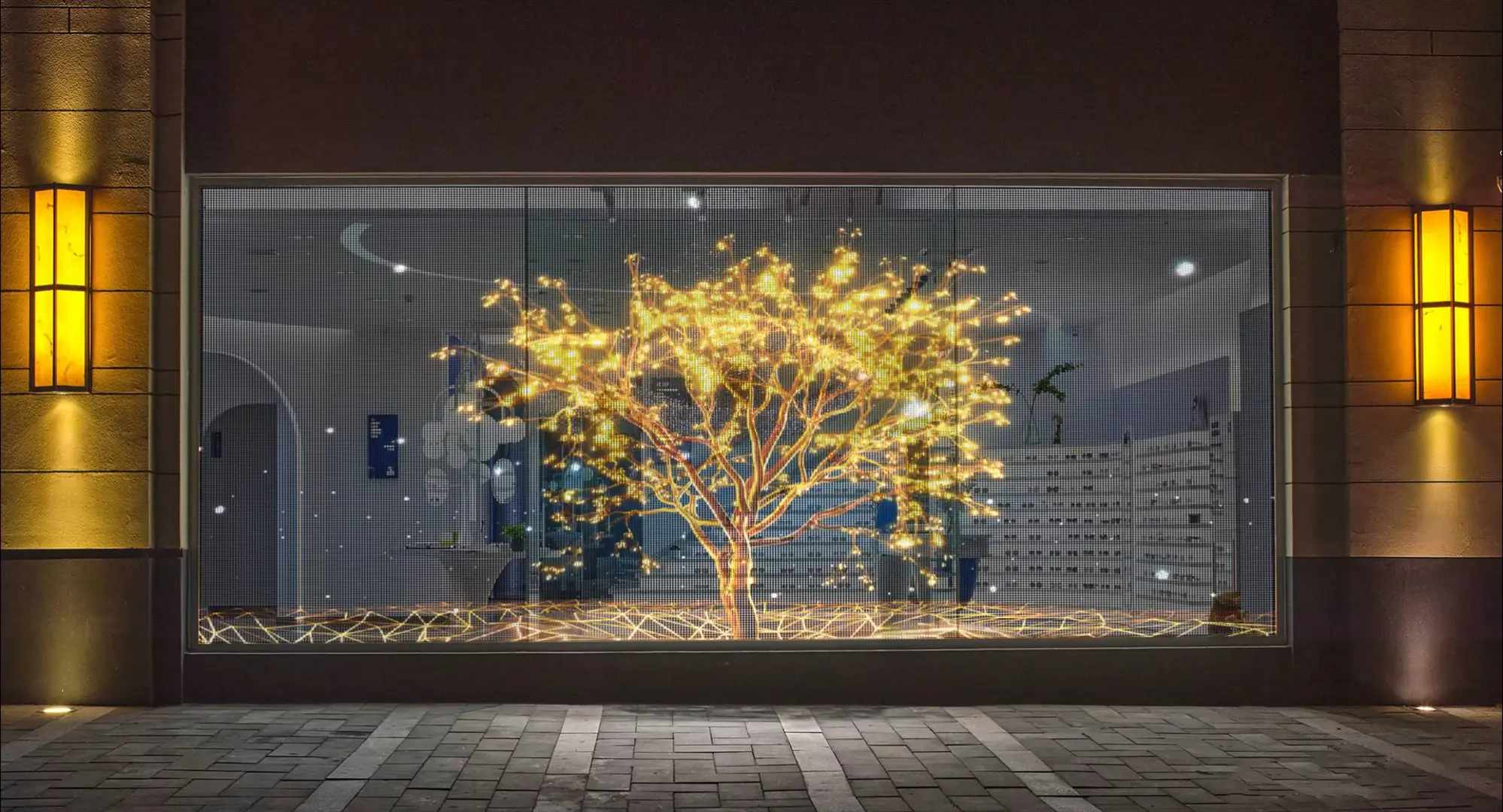

For grid screens on large malls, IP67 ratings ensure transparency and brightness hold up against elements. These displays, with modular wires and self-heat dissipation, rely on full seals to block moisture while letting heat escape through micro designs. A study in Optics Express (2021) notes that IP-rated fixtures in humid climates maintain 90% lumen output after 10,000 hours, versus 70% for lesser protections. This matters in traffic hubs like airports, where dust from crowds and rain from open areas test limits.

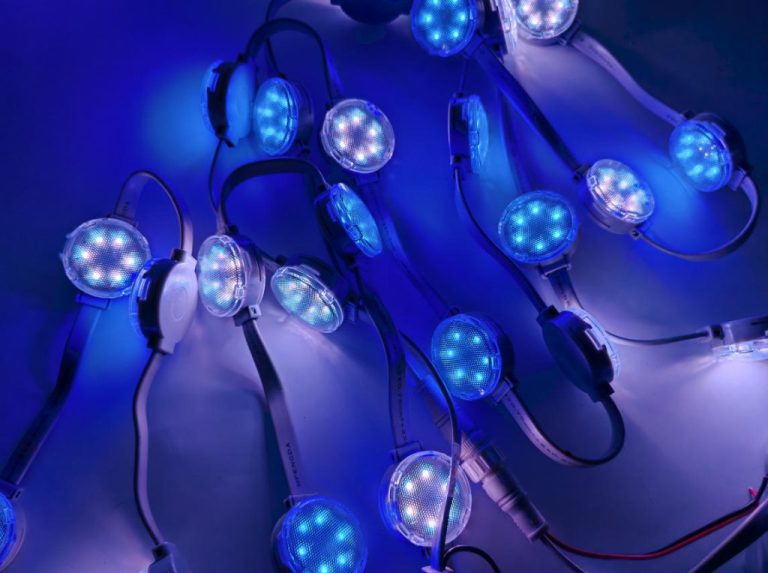

Point light sources for elevator handrails or automatic doors benefit similarly. Their mini encapsulation and optical prisms need robust IPs to fuse with VR or AR elements without failing. Real protection for outdoor LED grid screens comes when ratings align with site demands—IP68 for submersion-prone bridges, say—keeping visuals sharp and maintenance low.

Real Protection Cases in Action

Real-world cases show IP ratings turning potential disasters into smooth operations. Consider a high-speed rail station where LED point lights line glass barriers. Exposed to passenger traffic and occasional spills, IP67 seals keep dust out and water from seeping, maintaining clear signals for years. In one installation, fixtures endured daily cleaning jets without a single outage, proving how sealed LED fixtures heat issues stay minimal when protection is solid.

Another example: a city landmark with curved grid screens on steel structures. Here, bolt-spliced wires and IP67 designs handled wind-driven rain, preserving the cultural tourism promo displays. Data from the installation logged over 50,000 hours with no decay, aligning with findings from IEEE Transactions on Device and Materials Reliability (2019), where proper IPs extended life by blocking contaminants that accelerate wear.

For enterprise exhibit halls, flexible transparent screens with high IPs blend into glass windows, resisting fingerprints and humidity. One project saw modules pasted directly, their micro-hole heat tech working alongside seals to avoid thermal buildup. These stories underline LED lifespan factors—ratings aren’t hype; they’re the shield that lets creativity flow without interruptions.

Buyer’s Guide to Selecting IP-Rated Fixtures

Navigating purchases starts with matching IPs to your site’s grit. For urban buildings, aim for IP67 or higher to cover dust and jets; in coastal areas, IP68 guards against salt spray. Check beyond the code—look at how designs integrate vents for heat dissipation in LED lights, ensuring longevity in sealed spots.

Test certifications matter. Fixtures passing ISO standards signal reliability, like those withstanding submersion tests. In bids, request lifespan curves showing heat impact on LED lifespan under rated conditions. For custom needs, like interactive sensors in exhibits, ensure IPs don’t compromise signal backups or power efficiency.

Common pitfalls: skimping on ratings for cost savings often backfires with early failures. Instead, factor in total ownership—durable builds cut replacements. Procurement pros can quiz suppliers on real-world data, like how their point lights fare in monsoons. This approach nets fixtures that perform, turning specs into success.

About Shenzhen XinHe Lighting Optoelectronics Co., Ltd.

Shenzhen XinHe Lighting Optoelectronics Co., Ltd., established in 2004, leads in LED innovation with a focus on point light sources and grid screens featuring proprietary tech. Based in Shenzhen, China, the company offers end-to-end services for architectural and advertising lighting, including design, budgeting, supply, and guidance. Holding certifications like ISO 9001 and ISO 14001, plus over 80 patents under the “Bean” brand, XinHe delivers products that excel globally, blending quality with efficient manufacturing for demanding outdoor applications.

Conclusión

Grasping IP ratings in architectural LED lighting unlocks real protection that stands up to nature’s tests. From dust-tight seals to submersion resistance, these codes ensure fixtures deliver lasting performance in challenging spots. For buyers, this knowledge means smarter picks that enhance projects while minimizing risks. Exploring these layers reveals how solid ratings fuel innovation without compromise.

FAQs

What do IP ratings in architectural LED lighting mean for outdoor durability?

IP ratings in architectural LED lighting indicate protection against solids and liquids, with higher numbers like IP67 offering dust-tight and immersion resistance. This ensures fixtures like grid screens endure rain and dust, maintaining brightness in urban facades.

How does understanding IP ratings help with waterproof LED lights in sealed environments?

Understanding IP ratings guides selection for waterproof LED lights, where IP67 prevents moisture ingress in sealed setups. It addresses heat and decay issues, extending service life in applications like glass curtain walls.

Why is IP67 crucial for real protection for outdoor LED grid screens?

IP67 provides real protection for outdoor LED grid screens by blocking dust and allowing submersion, vital for longevity in weather-exposed installations. This level supports modular designs without compromising performance.

Can higher IP ratings improve LED lifespan factors in architectural projects?

Higher IP ratings improve LED lifespan factors by shielding internals from contaminants, reducing thermal stress in high-power setups. For point lights in exhibits, this means consistent output over extended periods.

What should buyers look for in IP-rated architectural LED point lights?

Buyers should seek IP-rated architectural LED point lights with certified seals like IP67, ensuring resistance to elements while integrating heat management. This matches project needs for reliable, long-term illumination.