Outdoor LED lighting for building facades is often discussed as a visual upgrade. In real projects, it behaves more like a structural decision. Once fixtures are mounted on exterior surfaces, the building has to live with them through weather cycles, operational hours, and public scrutiny. Design mistakes do not always fail immediately. Many simply age badly.

Facade lighting sits in a difficult position. It is expected to enhance architecture without overpowering it, guide attention without distraction, and remain consistent long after construction teams leave the site. That balance is harder to achieve than most early design discussions suggest.

This article looks at how outdoor LED lighting for building facades is actually designed, adjusted, and evaluated in commercial and architectural projects. Not as a catalog of lighting types, but as a sequence of decisions shaped by geometry, materials, installation reality, and long-term use.

Why Facade Lighting Is Not Just “Outdoor Lighting on a Wall”

Lighting a vertical surface is fundamentally different from lighting a ground plane. Reflections behave differently. Glare becomes more noticeable. Small misalignments are easier to spot from a distance.

In many projects, facade lighting is expected to perform multiple roles at once. It highlights architectural rhythm, supports brand presence at night, and sometimes functions as wayfinding for surrounding spaces. When these roles are mixed without priority, the result often feels inconsistent.

What separates strong facade lighting from average work is not brightness, but restraint. Knowing where light should stop is as important as knowing where it should land.

Start With Intent, Not Fixtures

Defining the Role of the Facade at Night

Before any fixture is discussed, the facade needs a clear nighttime role. Some buildings aim for landmark visibility. Others prioritize subtle texture and material expression. These goals lead to very different lighting strategies.

A glass curtain wall, for example, reacts poorly to excessive frontal lighting. Reflection dominates. A concrete or stone facade may absorb light and require a different approach altogether. Treating these surfaces the same often leads to disappointment during testing.

Design intent, once clarified, removes many options automatically. That narrowing is helpful, not limiting.

Geometry and Surface Detail Shape the Strategy

Facade geometry quietly dictates lighting behavior. Flat surfaces respond predictably. Deep reveals, fins, and layered structures do not.

When lighting designers ignore depth, shadows fall where they are least expected. Point-based solutions may highlight joints instead of surfaces. Linear approaches may exaggerate irregularities. These outcomes are not always visible in renderings.

This is where experience matters. Adjustments made on site—slight changes in angle, spacing, or mounting depth—often determine whether the facade reads as intentional or accidental after dark.

Sometimes, fewer fixtures placed with precision outperform a dense layout trying to correct itself.

There is usually a moment during night testing when the building looks “almost right.” That last step often has nothing to do with adding more light.

Choosing Outdoor LED Fixtures in Real Projects

Matching Fixtures to Conditions, Not Assumptions

Outdoor LED fixtures are frequently selected based on specifications alone. In practice, orientation, exposure, and mounting method influence performance just as much.

A fixture installed under an overhang experiences a very different environment from one exposed on a high-rise facade. Heat dissipation, moisture paths, and maintenance access all change. Designs that treat every exterior surface as equivalent rarely hold up.

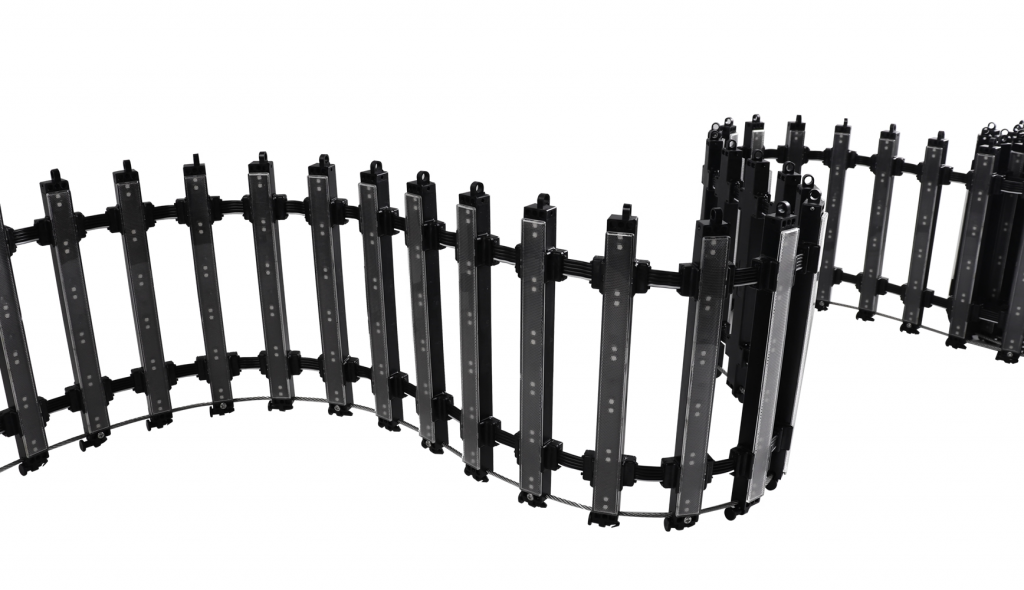

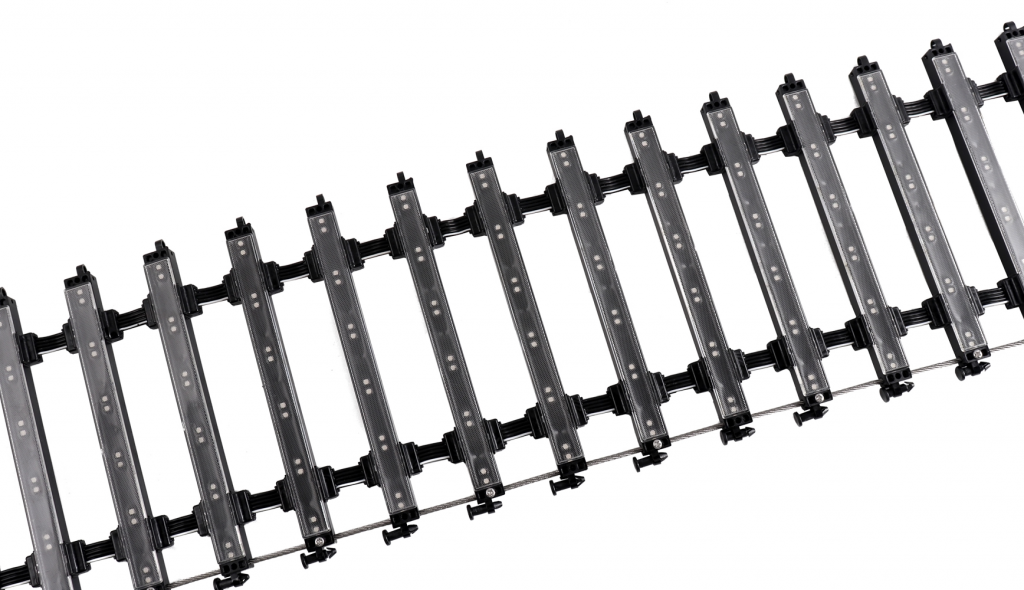

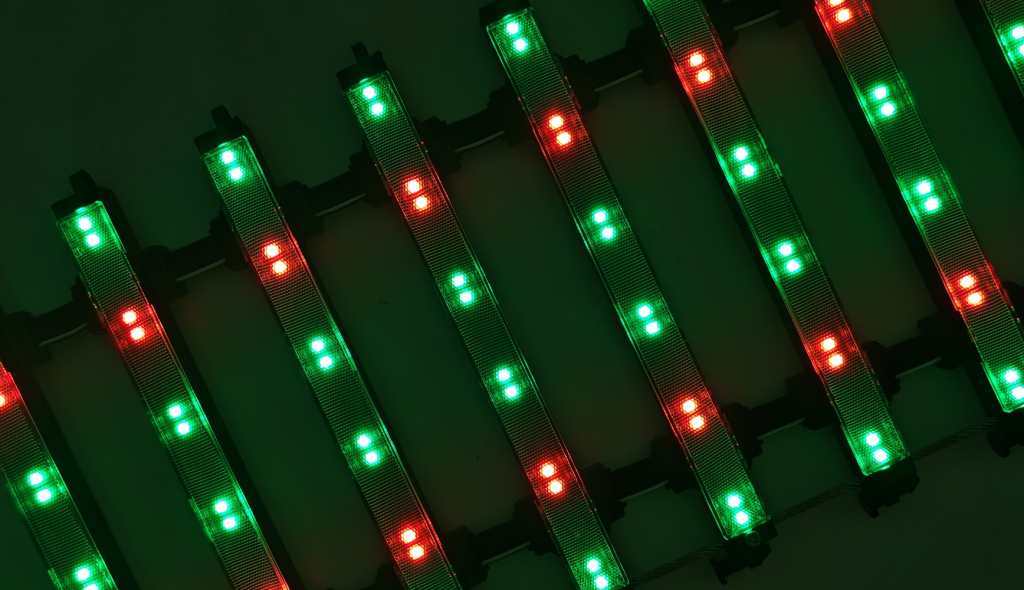

In facade applications, consistency across production batches also matters. Color shift or output variation becomes visible when fixtures are aligned in long vertical or horizontal runs.

Beam Control and Visual Comfort

Beam angle selection is often simplified into narrow versus wide. On facades, the relationship between beam spread and spacing is more important than either value alone.

Tighter beams spaced too far apart create striping. Wider beams placed too closely flatten texture. Finding the balance usually requires testing, not formulas. This is especially true on mixed-material surfaces.

Visual comfort is another factor that rarely appears in specifications. Excessive contrast or uncontrolled spill can make public spaces feel uncomfortable, even if technical targets are met.

Installation Reality Changes Design Outcomes

Even a solid design can be undermined during installation. Cable routing decisions, mounting tolerances, and drainage details shape long-term results.

Outdoor LED lighting for facades is exposed to constant thermal movement. Fixtures mounted without allowance for expansion often shift slightly over time. The change may be small, but alignment issues become obvious once the lighting pattern repeats across a large surface.

Projects that include early installation guidance tend to adapt faster. Minor adjustments made during initial zones prevent repeated corrections later.

Budget Decisions That Affect the Final Result

Facade lighting budgets are often fixed early. What changes is how that budget is distributed.

Spending more on fewer, better-matched fixtures sometimes reduces total cost by simplifying installation and lowering maintenance frequency. Conversely, selecting lower-cost options without considering access and replacement cycles often leads to higher long-term expense.

This is where collaboration between designers, contractors, and suppliers becomes valuable. Early discussion about constraints saves far more time than late corrections.

About Shenzhen XinHe Lighting Optoelectronics Co., Ltd

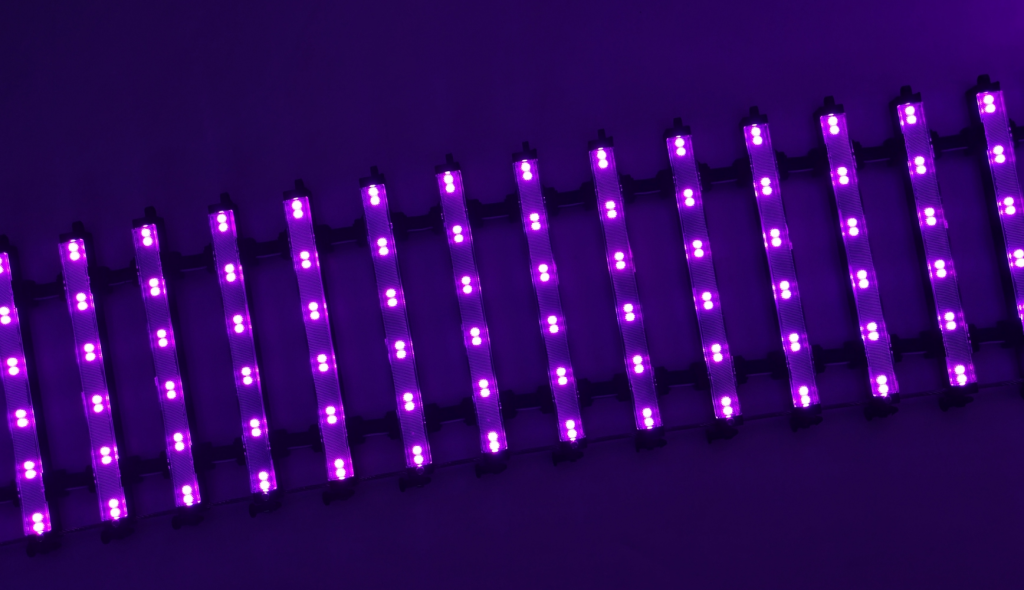

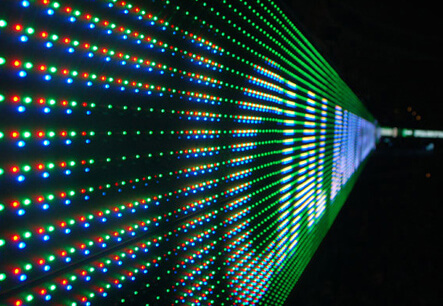

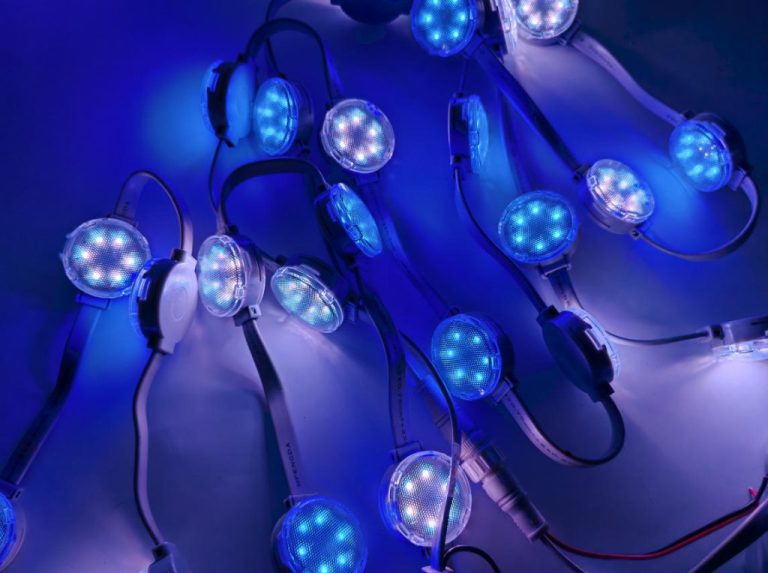

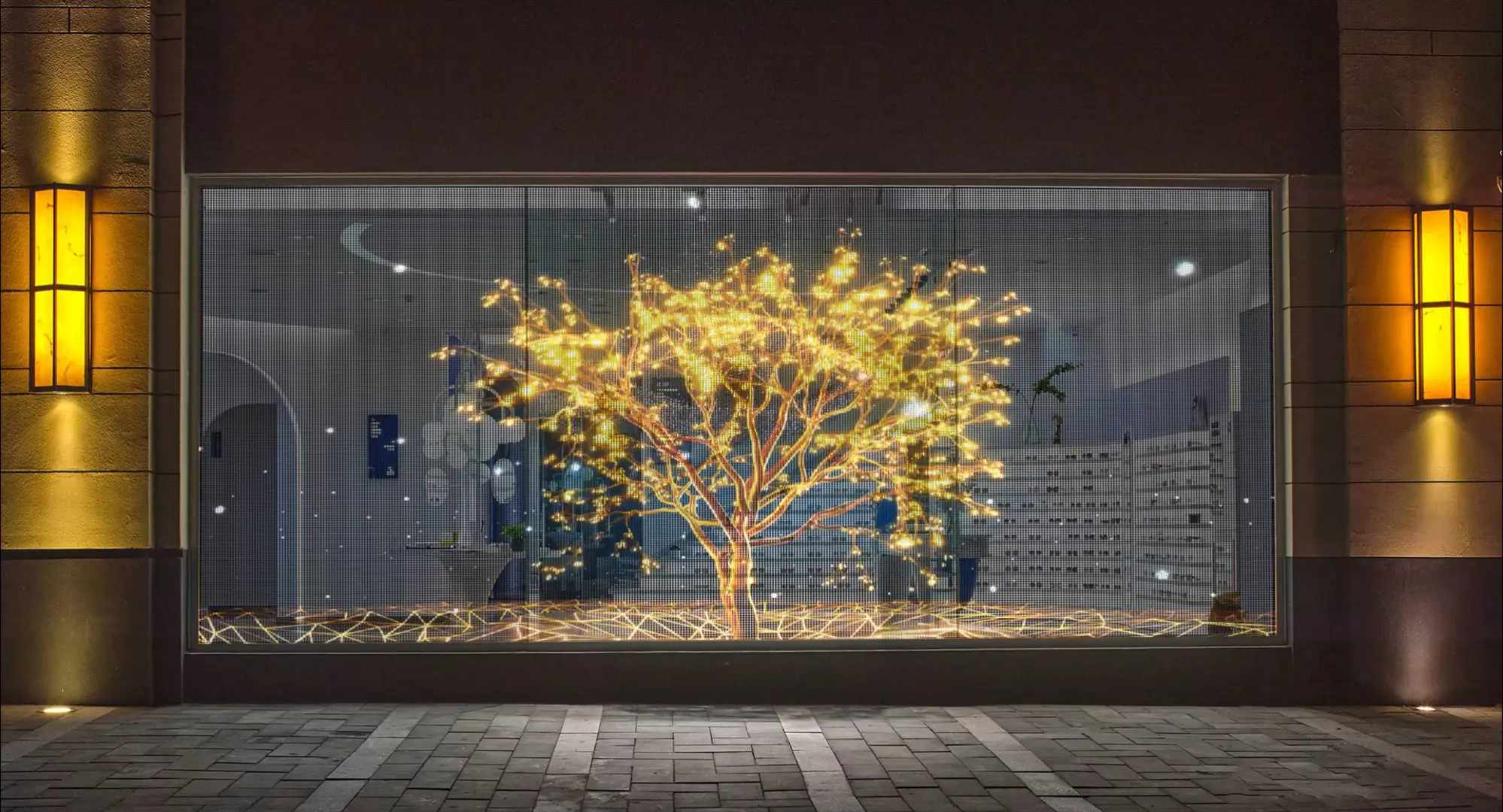

Shenzhen XinHe Lighting Optoelectronics Co., Ltd has been active in architectural and landscape lighting projects since 2004, with a focus on LED point light sources, grid-based display systems, and facade-oriented lighting solutions. The company supports large-scale projects through design coordination, project budgeting, product supply, and on-site technical guidance.

With established production processes and certified quality and environmental management systems, XinHe Lighting works with projects where long-term stability and consistency matter. Its experience across different facade structures and installation environments reflects a practical understanding of how outdoor LED lighting performs beyond initial testing.

Conclusión

Designing outdoor LED lighting for building facades is less about achieving a perfect visual on day one and more about creating a system that continues to feel right over time.

Buildings change. Environments change. Good lighting adapts quietly. When decisions are made with context, geometry, and long-term use in mind, the facade becomes part of the city’s nighttime language rather than a temporary statement.

FAQs

How early should facade lighting be considered in a building project?

Earlier than many teams expect. Once facade details and access points are fixed, lighting options narrow quickly.

Is brighter lighting always better for building facades?

Not necessarily. Excessive brightness often reduces texture and increases glare, especially in pedestrian areas.

Can point-based LED solutions work on large facades?

Yes, particularly when used selectively to emphasize structure or detail rather than uniform coverage.

Why does facade lighting sometimes look uneven after installation?

Spacing, surface variation, and installation tolerances usually play a bigger role than fixture quality alone.

What role does a lighting manufacturer play beyond supplying products?

Experienced manufacturers often support design validation, installation guidance, and consistency across production, which directly affects final results.