In commercial projects, outdoor LED lighting installation mistakes rarely show up as a dramatic failure on day one. More often, they arrive as a slow drip of callbacks: uneven brightness that becomes obvious only at night, intermittent flicker after the first heavy rain, or a row of fixtures that “meets spec” but still looks wrong once the building is active. The root cause is usually not the idea on the drawing. It is the gap between design intent and job-site reality—mounting geometry, cable handling, drainage paths, and commissioning discipline.

This article focuses on the most common installation errors that drive rework and early degradation in architectural facades, media facade systems, exterior signage, and large landscape or public-space lighting. For the broader design framework that explains why spacing, beam choice, and real exposure conditions matter so much, reference outdoor LED lighting decisions that hold up after installation.

Why Installation Is Where Good Designs Get Undermined

A lighting system can be “correct” on paper and still fail in the field because installation is the first time the project confronts real constraints: irregular substrate surfaces, access limitations, cable routing conflicts, thermal movement, and water paths that were never visible in the renderings.

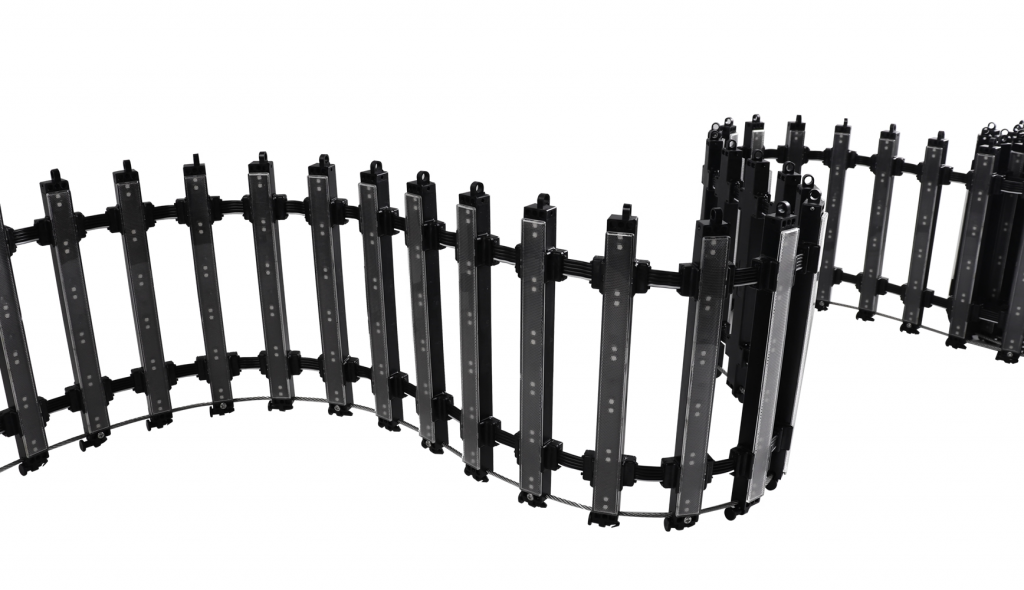

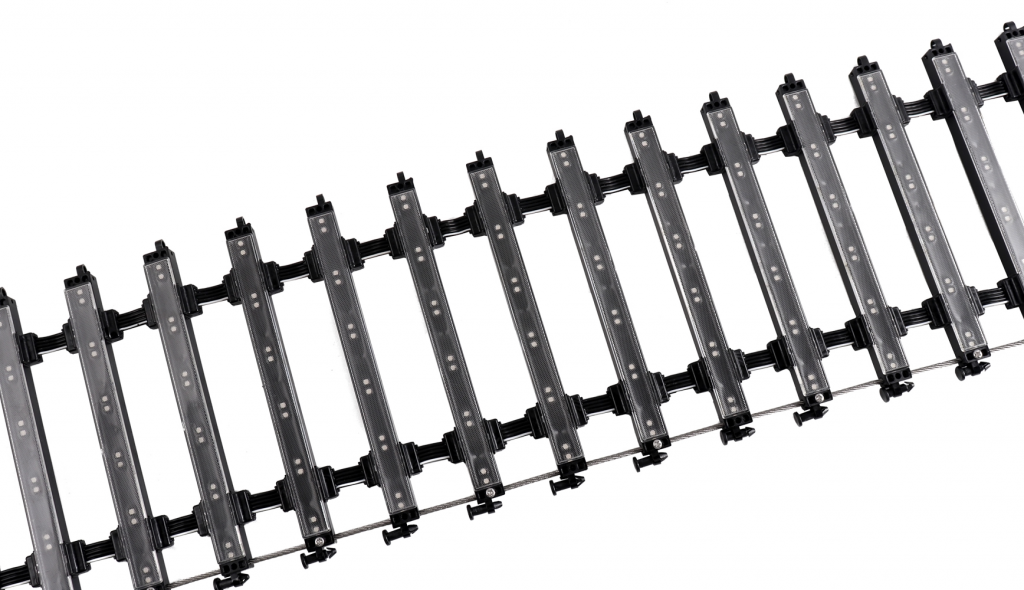

There are three patterns that repeat across regions and project types. Cables get pulled too tight. Fixtures get mounted with no tolerance for expansion. Drainage paths get blocked by brackets that looked harmless during assembly. These are not rare mistakes; they are the standard failure modes that turn a clean design into a maintenance problem.

When the goal is fewer callbacks, installation must be treated as a controlled process, not an improvisation. That means the project needs an agreed geometry, a cabling method that respects movement, and a field test approach that catches problems before the last lift leaves the site.

Mechanical Installation Mistakes: Geometry, Movement, and Drainage

Mounting geometry gets treated as “close enough”

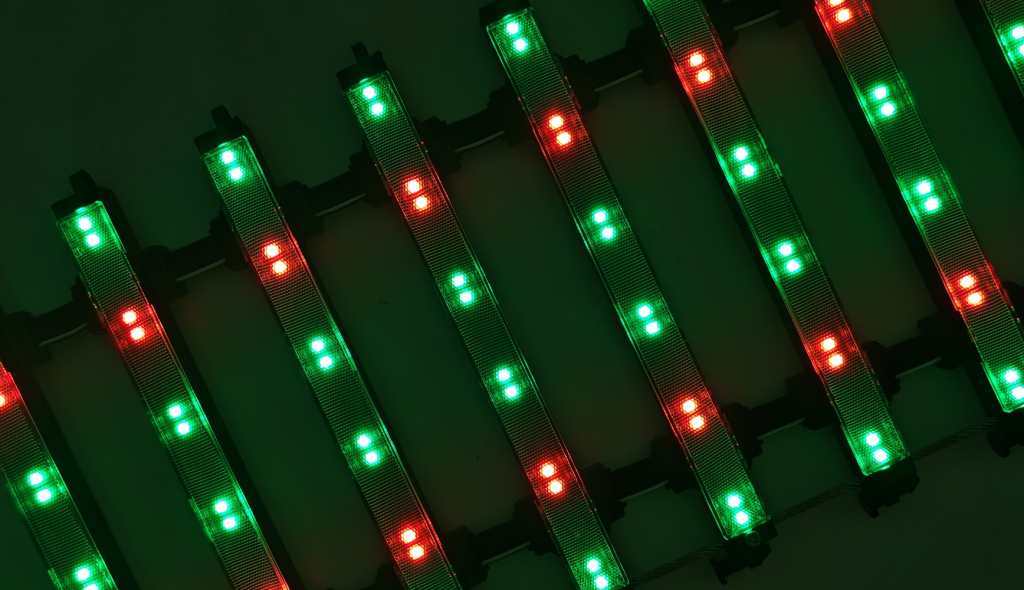

Outdoor lighting is unforgiving because the environment supplies long-term contrast. A facade line that looks aligned at 4 p.m. can look uneven at 9 p.m., especially when point-based systems repeat across a large surface. Small shifts accumulate: a few millimeters here, a few degrees there. After several floors, the pattern reads as sloppy, even if every fixture technically works.

The practical fix is not extra brightness. It is consistent geometry. The mounting reference must be repeatable, and the tolerance must be defined before crews start. Once “close enough” becomes the norm, the site may still pass basic functional checks, but the visual intent is permanently compromised.

No allowance for thermal movement

Exterior assemblies move. Metal expands and contracts. Sealants flex. Cable jackets stiffen in cold and relax in heat. If fixtures are mounted rigidly with no allowance, the system stresses itself every day. That stress often shows up later as loosened fasteners, shifted aim angles, cracked seal interfaces, or damaged cable entry points.

The simplest job-site habit that prevents this is treating movement as a known condition. Fixtures should be mounted with a tolerance strategy that matches the substrate and exposure. Cable routing should include slack in the right places—controlled slack, not messy loops—so the system can move without pulling on connectors.

Drainage paths get blocked by “harmless” hardware

Water rarely enters from where teams expect. In outdoor installations, water follows gravity, wind pressure, and surface tension. A bracket that blocks a runoff channel can turn a brief rain event into standing moisture at the cable entry or seam. Even a sealed fixture can be compromised when installation creates a pocket where water sits for hours.

This is why “IP rating” cannot be treated as a complete safety net. Real protection depends on orientation, drainage, cable entry method, and thermal movement—variables that are defined during installation, not at the factory.

Electrical and Cabling Mistakes: Voltage Drop, Sealing, and Segmentation

Voltage drop gets discovered after everything is closed

Long runs and distributed point systems are where voltage drop turns into visible inconsistency. The first signs are often subtle: the end of a run looks slightly dimmer, color appears shifted under load, or flicker appears during scene changes. Teams sometimes respond by increasing supply output or swapping power supplies late, which creates new risks and uneven stress across the system.

A better approach is to validate voltage at the far end of the run before final sealing and permanent closure. That field measurement, done early enough, prevents the most expensive kind of fix: reopening completed areas to re-route power.

Connector sealing is treated as a product feature instead of a workmanship result

Outdoor electrical reliability is frequently lost at the interface: connector seating, gasket compression, cable jacket damage during stripping, or inconsistent potting practices. These issues often cause intermittent faults that are difficult to trace because the system can pass initial power-on checks and still fail after rain or freeze–thaw cycles.

The job-site standard should be repeatability: the same connector handling method, the same seating verification, the same strain relief pattern, and the same routing that prevents rubbing against sharp edges. When these are not standardized, “random” failures become inevitable.

No segmentation plan means every fault becomes a major investigation

In large facades and perimeter systems, troubleshooting speed matters. If a project has no segmentation strategy—no logical zones, no documented circuit boundaries, no clear isolation points—then one failed node can force a broad shutdown to locate a single issue. That turns minor faults into expensive site visits.

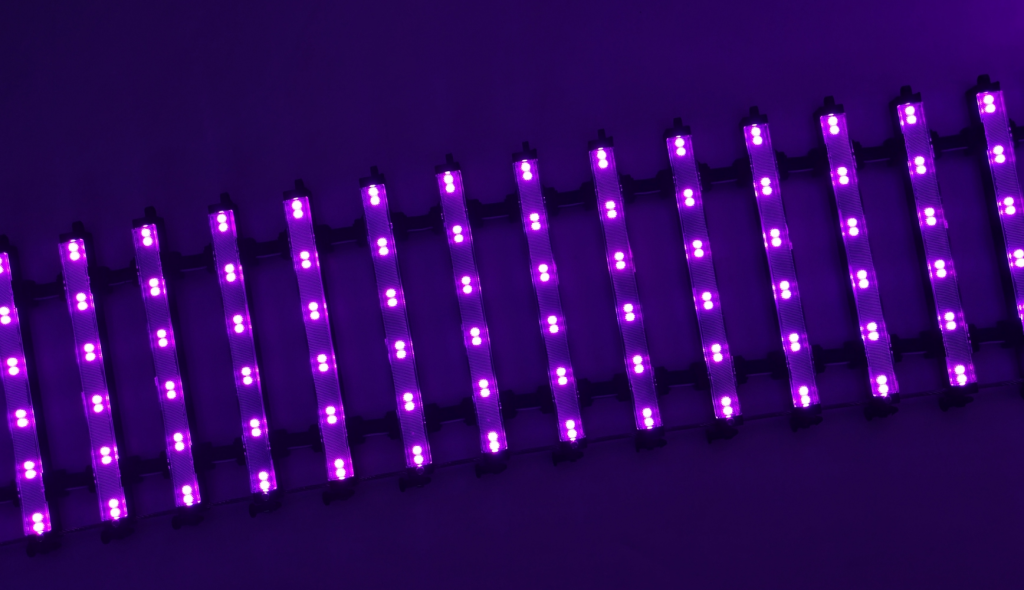

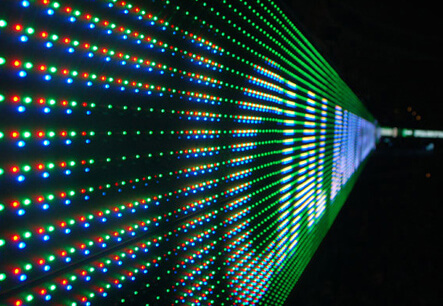

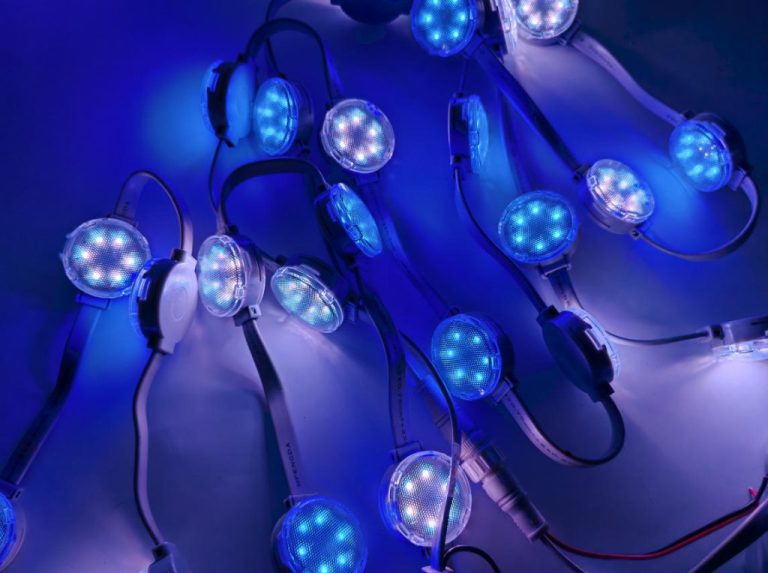

Segmentation is not only a controls topic; it is an installation design choice. It needs to be agreed before crews pull cable and close cavities. For teams comparing fixture families and system formats for long outdoor runs, review LED point light sources and grid-screen systems for outdoor projects.

Optical and Layout Mistakes That Only Reveal Themselves at Night

Mis-aiming creates glare, spill, and client complaints

Glare is rarely visible in daytime walkthroughs. It becomes obvious when pedestrians, drivers, or occupants view the light source from real sightlines at night. A fixture aimed a few degrees off can push light into windows, across neighboring properties, or into the eyes of people approaching an entry.

The field symptom is predictable: the site is “bright,” but users feel uncomfortable, and the space looks harsh. Fixing glare after installation often means re-aiming, re-mounting, or adding shielding, which is costlier than getting aim discipline right during initial setup.

Spacing intent gets broken by installation shortcuts

Many projects reach a moment in night testing where the team says, “It’s bright enough, but it still feels off.” That reaction usually traces back to spacing. Narrow beams spaced too far apart create visible breaks. Wider beams placed closer can improve uniformity and reduce the perception of patchiness, but only if installation preserves the layout.

Shortcuts such as “adjusting spacing to avoid obstacles” without a plan often create inconsistent rhythm. In architectural lighting, rhythm is the design. When the rhythm is broken, the system never fully recovers through tuning alone.

Layer responsibility gets confused on site

Outdoor lighting works best when layers have clear jobs. One layer supports safety and movement. Another supports structure and emphasis. When accent lighting is forced to carry functional needs, it can look dramatic in early photos, then feel wrong once people use the space nightly.

Install teams can unintentionally create this outcome by changing aiming, swapping fixture positions, or reducing fixture count in functional zones. Preventing it requires a commissioning review that checks not only “does it light” but “does each layer still do its intended job.”

Thermal and Weather Mistakes: Heat Buildup and Real Exposure

Heat is ignored because it does not fail loudly

Many outdoor systems do not “break.” They fade. Output gradually declines. Color stability shifts. Drivers run hotter than expected. This is why heat is often called the silent variable in outdoor lighting: it damages performance over time rather than triggering immediate shutdown.

Heat problems are often created by installation: mounting that traps airflow, placing drivers in sealed cavities without thermal consideration, or clustering power components where they bake each other. Summer nights then become a stress test the project did not plan for.

Orientation and airflow get treated as aesthetic choices

A fixture under an overhang behaves differently from one exposed on a high-rise facade. Even within the same building, microclimates exist: sun-heated metal, wind funnels at corners, and shaded zones that hold moisture longer. Installation needs to acknowledge those differences because they determine how seal materials age and how connectors handle condensation cycles.

“Rated outdoor” gets mistaken for “safe in every installation”

Outdoor-rated components still require correct installation context. The pillar guide describes how “solid outdoor fixtures can fail when installed without allowance for movement and moisture,” and that early on-site guidance often prevents repeated corrections across zones. This is precisely why a mistakes-focused cluster article matters: it turns that principle into measurable site actions.

Commissioning and Acceptance Mistakes: Testing, Documentation, and Maintenance Reality

Acceptance is done in daylight, then problems surface later

Daytime sign-off can miss the issues that drive complaints: glare from approach angles, unevenness across long runs, hotspots on reflective materials, and spill into unwanted areas. A night commissioning process should be treated as non-negotiable for architectural and facade systems, because night is the actual operating condition.

Night checks should confirm that the visual intent holds from real viewing distances, not only from the installation lift. It should also confirm that dimming behavior is stable, transitions are smooth, and zones behave consistently under scene changes.

Batch consistency and replacement planning are neglected

Large projects often extend in phases. Replacement events are inevitable. If the project does not plan for consistency across production runs and the logistics of future replacements, visible mismatch becomes a long-term risk. The pillar content highlights that color temperature in outdoor projects is ultimately about consistency, particularly across repeated patterns and aligned runs.

Handover documentation is too thin to support maintenance

A site that lacks as-built documentation forces maintenance teams to guess. That leads to slow troubleshooting, accidental damage during service, and recurring costs. The handover should reflect how the system was actually installed, including zoning boundaries, power distribution intent, and practical access points.

Supplier Collaboration: Preventing Rework Starts Before the Crew Arrives

Installation mistakes are often symptoms of earlier gaps. If the project does not define exposure conditions, access limitations, and maintenance expectations before procurement, the installation team is forced to improvise in the field.

Upfront pricing also hides long-term cost. The pillar guide notes that energy usage, access for maintenance, replacement cycles, and consistency across production runs shape the real expense, and that supplier experience reduces friction later through verification support and adaptation to site conditions.

For B2B buyers, the practical takeaway is straightforward: fewer callbacks come from treating installation context as a selection input, and from working with a partner that can support design coordination, budgeting alignment, and on-site guidance when the first zones are built. When project constraints require non-standard mounting details, cable layouts, or control integration, ODM/OEM support for custom mounting, wiring, and commissioning requirements can reduce redesign and late-stage rework.

About Shenzhen XinHe Lighting Optoelectronics Co., Ltd

Shenzhen XinHe Lighting Optoelectronics Co., Ltd was established in 2004 and focuses on the research, development, and application of point light sources and grid-screen systems for architectural landscape and advertising lighting projects. The company also describes its role as more than product supply, supporting projects through scheme design coordination, engineering budget support, product provision, and on-site guidance—services that are directly relevant when installation discipline determines long-term stability—see Shenzhen XinHe Lighting Optoelectronics Co., Ltd company profile and project support.

Conclusión

Most outdoor LED systems do not fail in a dramatic moment. They drift into trouble: moisture issues that emerge after the first season, alignment that slowly looks “off,” output that fades unevenly, or service cycles that become more frequent than planned. The projects that avoid costly callbacks tend to share one habit: installation is treated as an engineered process. Mounting geometry is controlled, thermal movement is respected, drainage is protected, electrical runs are validated before closure, and commissioning is done under real nighttime conditions. When those steps are standard, the lighting system is far more likely to stay consistent long after the construction team leaves.

FAQs

What are the most common outdoor LED lighting installation mistakes?

The most common issues involve mechanical and environmental realities: cables pulled too tight, fixtures mounted without tolerance for expansion, and drainage paths blocked by brackets. These lead to early sealing failures, shifting alignment, and long-term reliability problems.

Why do outdoor LED fixtures fail after rain even with a high IP rating?

IP ratings describe test conditions, but real protection depends on installation context—orientation, drainage, cable entry method, and whether water can sit against seams or connectors. Blocking runoff paths or stressing cable entry points often creates failures that the rating alone cannot prevent.

How can voltage drop cause flicker or uneven brightness on long runs?

Voltage drop reduces available power at the far end of long circuits, which can trigger dimmer output, unstable behavior during dimming, or intermittent flicker under load. The most cost-effective prevention is validating end-of-run voltage before final sealing and closing of the installation.

What should be checked during nighttime commissioning for facade and signage projects?

Night commissioning should verify glare from real approach angles, uniformity across repeated patterns, spill boundaries, and stable dimming or scene transitions. Many problems are invisible in daylight and become obvious only under real operating conditions.

How does supplier support reduce callbacks in large outdoor LED projects?

Large projects benefit when suppliers can support verification, adapt to site conditions, and maintain consistency across production runs. Early on-site guidance often prevents repeating the same corrections across zones, which directly reduces rework and long-term service cost.