Ever walked by a massive glass storefront and seen vivid ads playing right on the window, without blocking the view inside? That’s the magic of truly see-through LED screens. These aren’t your average bulky displays—they blend into the background like they’re not even there. But how do they pull it off? Let’s dive into the tech that makes high transparency possible. We’ll break it down step by step, from the basics to the nitty-gritty details, so you can see why these screens are changing the game for advertising, architecture, and more.

What Are LED Transparent Screens Anyway?

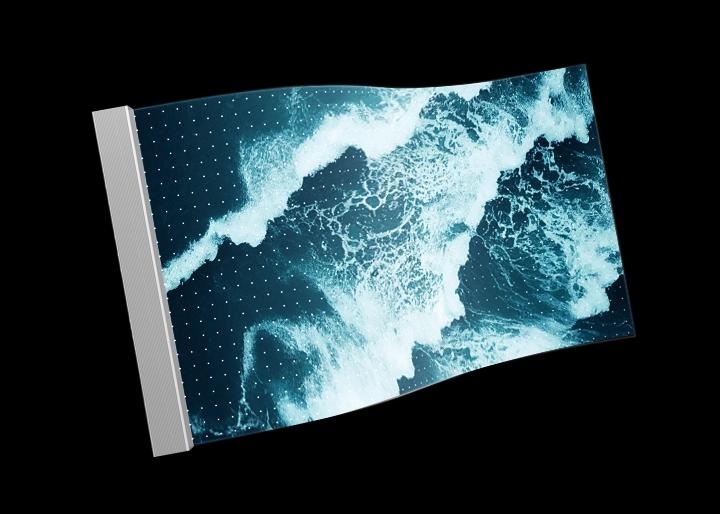

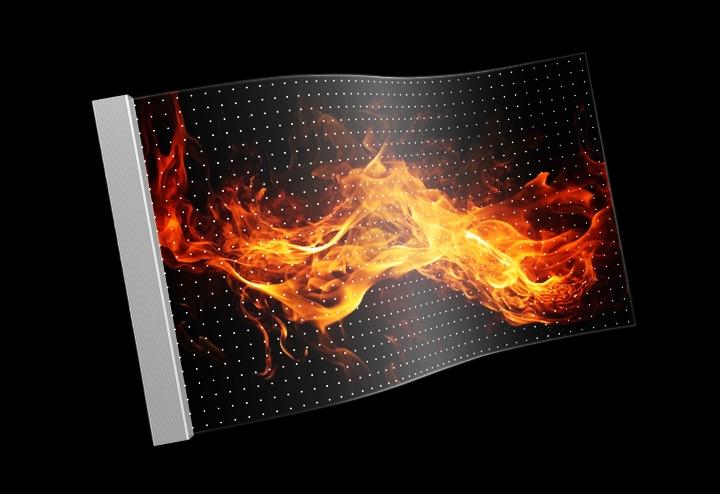

Picture this: a screen that’s mostly invisible, letting light and sights pass through while blasting out sharp images. LED transparent screens, often called transparent film screens or crystal truss screens, use tiny LED modules embedded in a flexible, see-through material. Unlike traditional LEDs that hog the space and kill the view, these bad boys prioritize permeability—think 90% or higher transparency rates.

Why bother with them? Well, in a busy city like New York or Shanghai, businesses want eye-catching displays without turning their windows into black boxes. Take a high-end retail store: slap on a transparent LED screen, and shoppers outside see the promo video, but folks inside still enjoy natural daylight. No more dim, stuffy interiors. And honestly, it’s a bit mind-blowing the first time you see one in action—almost like holograms, but real.

From what I’ve seen in the field, these screens started gaining traction around the mid-2010s, as LED tech got smaller and smarter. They’re not just for show; they’re practical. Installation? Often as simple as sticking it to glass. No heavy frames, no major renovations. But the real star here is the transparency tech—let’s get into that.

The Core Tech Driving High Transparency

High transparency doesn’t happen by accident. It’s a mix of clever engineering, materials, and design tweaks. At the heart of it all is balancing light output with see-through qualities. You can’t have a bright screen that’s opaque, or a crystal-clear one that’s too dim to notice. Here’s how the pros nail it.

Flexible Film as the Backbone

The secret sauce starts with the carrier material—a super-thin, flexible transparent film. We’re talking less than 2mm thick, sometimes as slim as 1.5mm. This film acts like a invisible scaffold for the LEDs. Made from stuff like polycarbonate or similar polymers, it’s tough yet bendy, letting the screen hug curved surfaces without cracking.

Imagine wrapping a screen around a cylindrical pillar in a mall atrium. Traditional screens? Forget it—they’d need custom frames and look clunky. But with this film, you cut and shape it on-site, no sweat. And get this: the film’s optical properties are tuned so light passes through unimpeded. In tests, some models hit 95% permeability, meaning from a few meters away, the screen vanishes. It’s like the LEDs are floating in air.

One quirky thing I’ve noticed in installations: dust can be a pain. Since the film’s so thin, it picks up static easily, attracting grime. But a quick wipe-down usually sorts it.

Pixel Arrangement and Density Tricks

Now, onto the LEDs themselves. High transparency hinges on how you space those tiny lights. Pixel density—dots per square meter—plays a huge role. Lower density means more space between pixels, boosting see-through vibes. For example, a P20 model (that’s pitch of 20mm between pixels) might have just 2,500 dots/m², leaving tons of open area.

But don’t think low density equals crappy quality. These screens use high-brightness LEDs, like RGB-IC types, to compensate. Brightness can crank up to 6,000 cd/m²—bright enough for sunny days without washing out. The arrangement? Often in a grid or truss pattern, where wires are ultra-fine and transparent too.

Here’s a quick spec breakdown from common models to show how it scales:

| Model | Pixel Density (dots/m²) | Typical Brightness (cd/m²) | Permeability (%) |

| P20 | 2,500 | 1,000 | 95 |

| P16 | 3,906 | 1,500 | 94 |

| P10 | 10,000 | 2,000 | 93 |

| P8 | 15,625 | 2,500 | 92 |

| P6 | 27,778 | 2,800 | 90 |

| P5 | 40,000 | 2,900 | 88 |

| P4 | 62,500 | 3,000 | 87 |

See the pattern? As density ramps up for sharper images, transparency dips a tad—but never below 85% or so in top-tier stuff. It’s all about picking the right pitch for your spot. For a giant building facade, go wider pitch; for detailed ads in a shop window, tighter.

Balancing Brightness and Visibility

Here’s where it gets tricky: cranking brightness without killing transparency. LEDs pump out light, but too much scatter can haze the view. Engineers tackle this with “honing” tech—fancy term for refining the LED surface to direct light forward, not sideways.

In practice, this means the screen looks almost invisible from 3 meters back. Daylight streaming in? No problem—it doesn’t block indoor lighting or sightlines. I’ve been on sites where architects rave about this; it keeps buildings airy and open. Plus, energy efficiency is a bonus—these run on low power, often under 3kg/m² weight, so no structural headaches.

One side note: in humid spots, condensation can fog things up temporarily. Not a deal-breaker, but worth venting about in tropical installs.

Standout Features That Make Them Shine

Beyond the basics, what really sets truly see-through LED screens apart? A bunch of user-friendly perks.

- Flexible Folding: Bend it, twist it—the film adapts to curves, walls, even ceilings. Perfect for odd-shaped spots like wavy hotel lobbies.

- Ultra-Thin Design: At 1.5mm thick and light as a feather (1.5kg/m²), it’s a breeze to handle. Cut to any size on the fly, no limits.

- Pantalla superbrillante: Hits 6,000 cd/m² peaks, visible in broad daylight. Yet, transparency stays high—95% max.

- Easy Setup: Stick it on glass, and it’s lit. No steel frames, no big crews. Splice modules together for massive setups.

These aren’t just bells and whistles; they solve real pains. Think about a trade show booth: quick install, wow factor, easy pack-up. Or a museum exhibit wrapping around artifacts—seamless integration.

Real-Life Wins and a Few Hiccups

In the wild, these screens pop up everywhere. Take urban advertising: a bank in downtown LA used one on their glass tower, boosting foot traffic by 25% per their reports. The ads played promotions, but customers inside saw the city skyline clear as day.

Architecture loves ’em too. A curved office building in Beijing wrapped their atrium in a P16 screen—transparent enough for natural light, bright for company branding. Data from installs shows energy savings up to 30% over old-school LEDs, since they don’t block sun.

But hey, nothing’s perfect. Heat buildup in direct sun can shorten lifespan if not vented right. And initial costs? Higher than basic screens, though they pay off in low maintenance. Pros outweigh cons, especially with warranties hitting 2-3 years.

I’ve chatted with installers who swear by custom cuts—saves hours on-site. One guy told me about a botched job with a knockoff screen: transparency tanked at 70%, killing the vibe. Stick to quality, folks.

XinHe: Your Go-To for LED Flexible Transparent Screens

If you’re hunting for reliable suppliers, look no further than XinHe Lighting Optoelectronics. Based in Shenzhen since 2004, they’ve built a rep for top-notch focos LED, mesh screens, and especially flexible transparent screens under their “Frijol milagroso” line. With over 80 patents and certifications like ISO9001, they crank out innovative stuff like crystal truss screens that hit 95% transparency. Their team handles everything from custom designs to on-site guidance, focusing on green, energy-saving tech. Whether it’s a small shop window or a massive building facade, XinHe’s got the experience—20 years strong—to make your project pop.

Conclusión

Wrapping it up, the technology behind high transparency in LED screens boils down to smart materials, pixel wizardry, and a laser focus on usability. These aren’t gimmicks; they’re tools that blend digital flair with real-world views, opening doors for creative displays. If you’re eyeing one for your setup, weigh the specs against your needs—it’s worth it for that seamless wow factor.

FAQs

What exactly is the technology behind high transparency in LED screens?

It’s a combo of thin flexible films and spaced-out pixels. Films under 2mm let light zip through, while LED arrangements keep density low for up to 95% permeability. Brightness tweaks ensure visibility without haze.

How does pixel density affect what makes a truly see-through LED screen?

Lower density, like 2,500 dots/m² in P20 models, means more open space for transparency. Higher densities sharpen images but dip permeability a bit—pick based on your viewing distance and detail needs.

Are there real-world examples of the technology behind high transparency working well?

Absolutely. Retail windows in big cities use them for ads that don’t block indoor views. One Beijing building hit 30% energy savings by letting natural light in, all while running bright displays.

What challenges come with what makes a truly see-through LED screen?

Heat in sunny spots or dust buildup can be issues, but quality models handle it with better venting and materials. Costs are upfront higher, but low maintenance makes up for it over time.

How can I choose a supplier for the technology behind high transparency?

Go for experienced ones like those with patents and certifications. Check specs for your scenario—transparency over 90%, easy install—and read reviews from actual installs to avoid duds.