Outdoor LED lighting design usually enters a project late. Not always, but often. By the time it does, the building form is fixed, circulation paths are set, and budgets already carry pressure from other systems.

That timing explains a lot of problems people quietly accept later. Glare where there shouldn’t be any. Uneven brightness across a facade. Fixtures that technically meet specs but feel wrong once the site is active at night.

Lighting rarely breaks a project on day one. It wears it down over time.

This guide looks at outdoor LED lighting from the angle most commercial projects eventually face—what holds up after installation, after weather, after usage patterns settle in. Not everything here is neat. Real projects aren’t either.

Why Outdoor LED Lighting Is Usually Underestimated

There’s a habit in large projects to treat exterior lighting as a finishing layer. Something added once the “important systems” are solved.

That assumption doesn’t survive long in use.

Outdoor lighting shapes how people approach a building, how long they stay in surrounding spaces, and whether those spaces feel intentional or improvised. In mixed-use or commercial environments, lighting becomes part of navigation, not just atmosphere.

The shift to LED made this more obvious. Precision increased, but so did visibility of mistakes. LEDs don’t hide poor spacing or bad angles. They make them clearer.

Core Thinking Behind Effective Outdoor LED Lighting Design

Layering Is Less About Theory Than Control

Layered lighting sounds academic until you’re on site at night trying to correct shadows with fixtures already mounted.

In practice, layers are about responsibility. One layer handles safety and movement. Another handles structure and emphasis. When one layer tries to do both, compromises show up fast.

Some projects lean too hard on accent lighting to “carry” functional needs. It looks dramatic in early photos, then feels uncomfortable once people actually use the space.

That pattern repeats often enough to be worth mentioning.

Spacing and Beam Decisions Are Where Designs Quietly Win or Lose

Brightness is easy to specify. Distribution is harder.

On facades, narrower beams spaced too far apart create visible breaks. Wider beams, placed closer, often reduce fixture count while improving uniformity. It’s counterintuitive until you see it play out.

This is where outdoor LED lighting design stops being aesthetic and starts behaving like applied geometry. Simple adjustments here prevent later complaints that no amount of post-install tweaking can fully fix.

There’s usually a moment during site testing when someone says, “It’s bright enough, but it still feels off.”

That moment almost always traces back to spacing.

Choosing Fixtures Without Designing Yourself Into a Corner

Weather Resistance Is More Than an IP Rating

IP ratings are useful. They’re also incomplete.

Real exposure depends on orientation, drainage, cable entry, and thermal movement. A fixture rated well on paper can still fail if water has nowhere to go or heat has nowhere to escape.

Projects near coastal zones or dense urban areas with reflected heat see this faster than most. Failures don’t show up immediately. They appear after a season.

Teams that factor installation context into fixture selection tend to avoid repeat interventions.

Color Temperature Is About Consistency, Not Preference

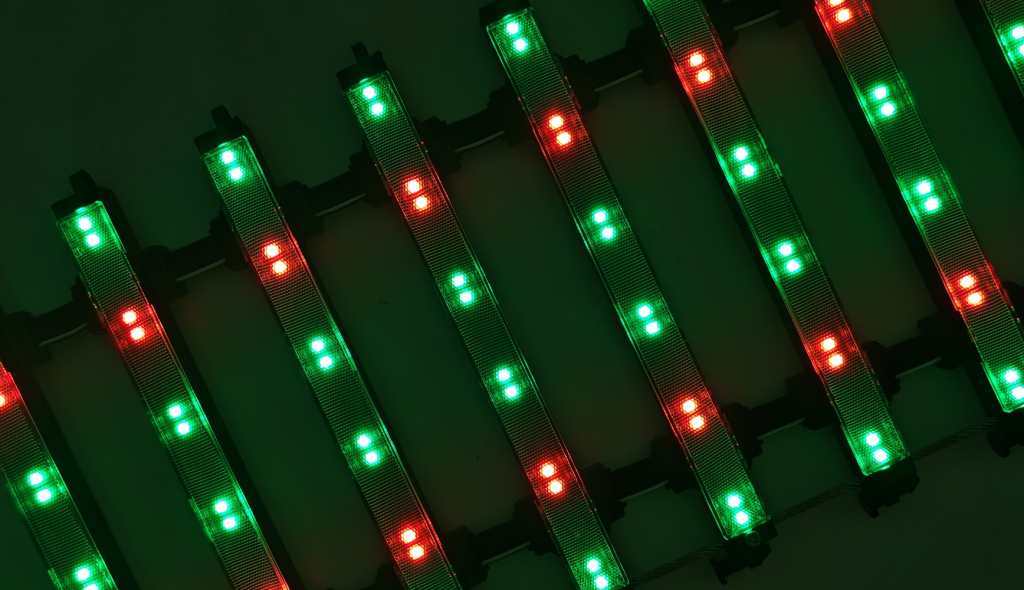

Discussions around color temperature often sound subjective. In reality, inconsistency causes more issues than the chosen number itself.

Warm tones suit hospitality and stone surfaces. Cooler tones emphasize glass and metal. Problems arise when batches don’t match or replacements drift slightly over time.

Large installations expose these shifts. Once visible, they’re hard to ignore.

Heat Management Is the Silent Variable

LEDs tolerate a lot, but not sustained heat. Poor thermal paths shorten life faster than most people expect.

Mounting orientation, airflow, and ambient conditions matter. Designs that ignore these factors may still pass initial tests, then degrade unevenly.

This isn’t dramatic. It’s gradual. Which is why it’s often overlooked.

Outdoor LED Lighting Applications Across Real Projects

Different environments reward different priorities.

Architectural facades favor control and restraint. Too much brightness flattens form. Landscape spaces benefit from transitions rather than uniform coverage. Large public installations often need visibility from distance without overwhelming nearby areas.

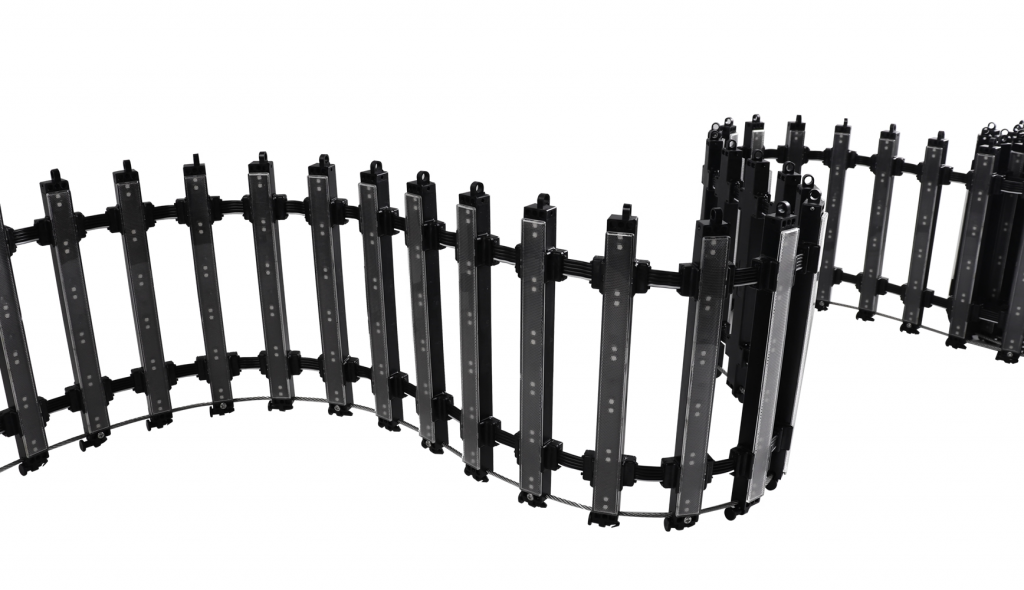

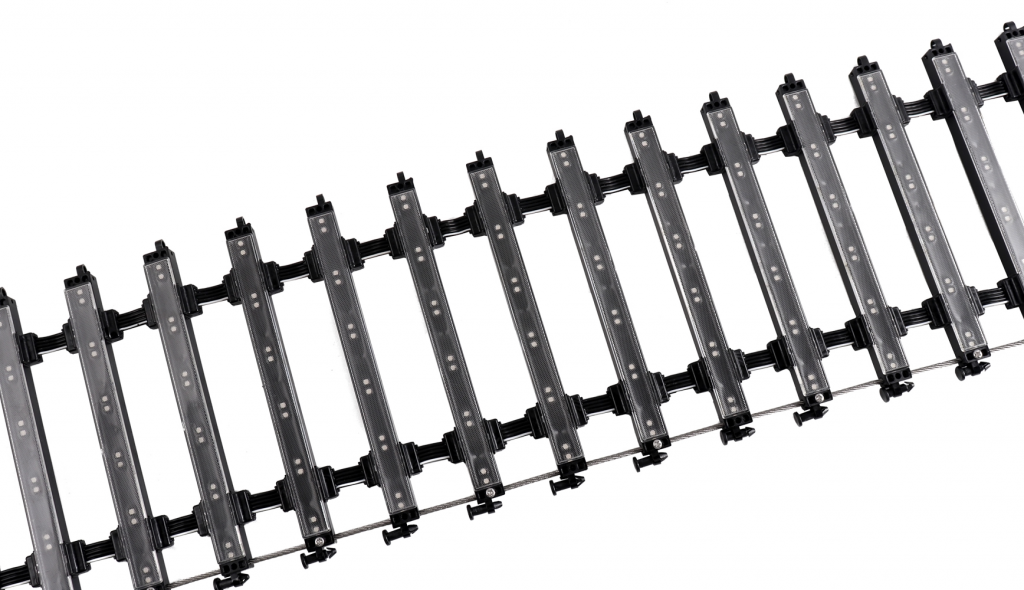

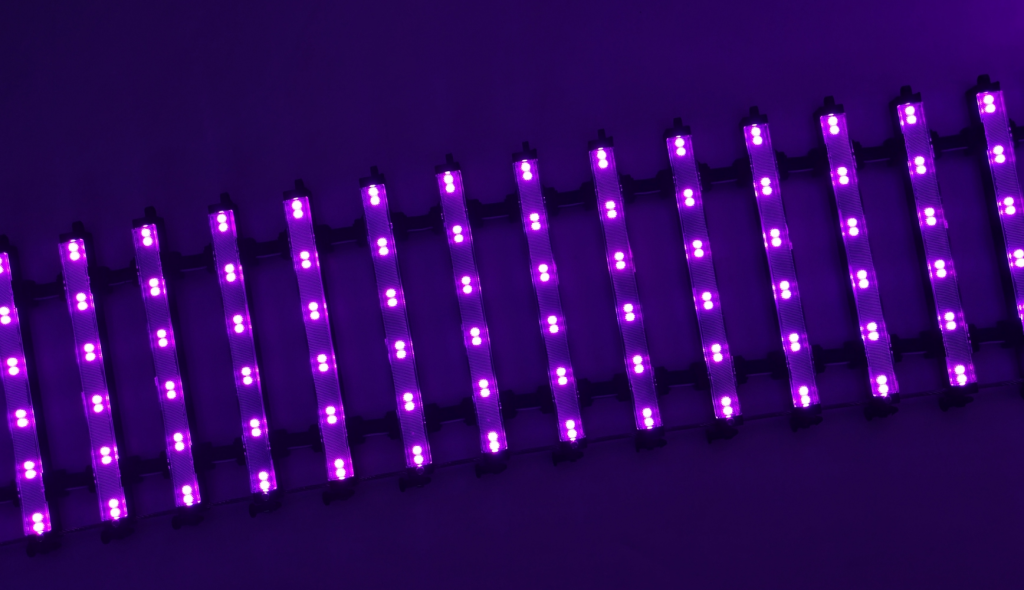

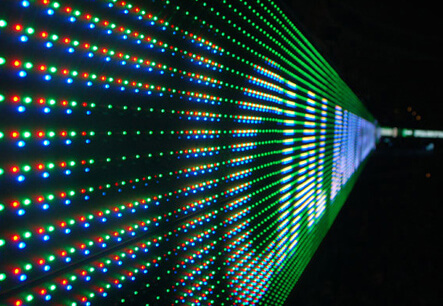

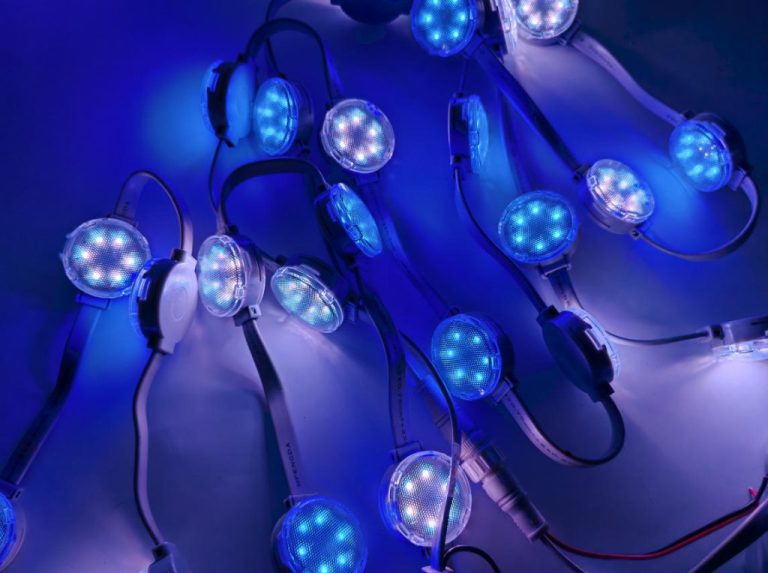

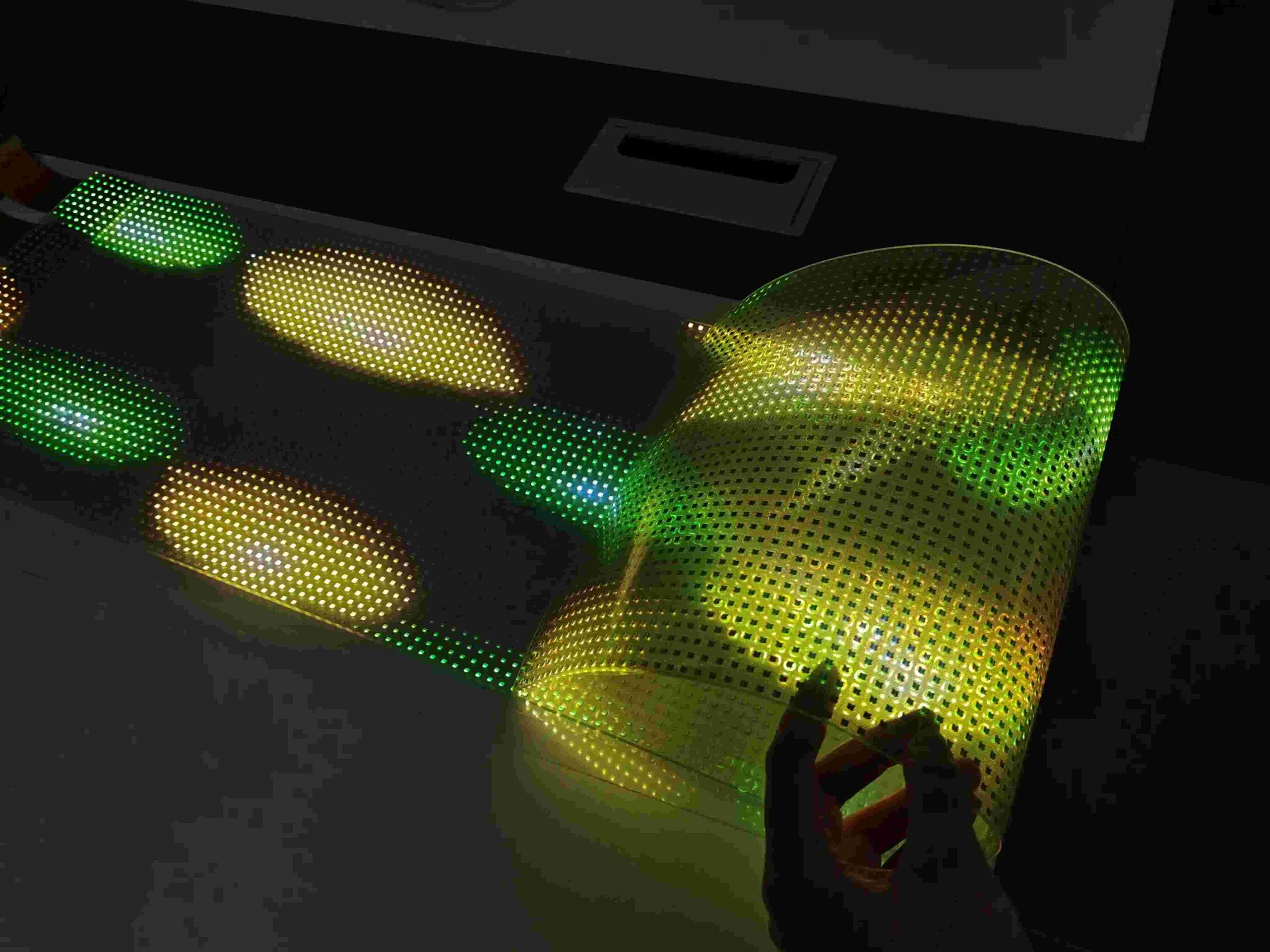

Point light sources, modular systems, and grid-based solutions are often combined in larger projects. That mix allows detail without locking the design into rigid geometry.

When people talk about “flexibility” in lighting, this is usually what they mean.

Installation: Where Good Designs Are Commonly Undermined

Installation doesn’t get much attention in design discussions, yet many issues originate there.

Cables pulled too tight. Fixtures mounted without tolerance for expansion. Drainage paths blocked by brackets that seemed harmless at the time.

Even solid outdoor LED fixtures can fail when installed without allowance for movement and moisture. Projects that include early on-site guidance usually avoid repeating the same corrections across zones.

It’s not about blame. It’s about anticipating what drawings don’t show.

Budgeting and Supplier Decisions That Affect Outcomes

Upfront pricing rarely reflects total cost.

Energy usage, access for maintenance, replacement cycles, and consistency across production runs all shape long-term expense. A slightly cheaper fixture that needs early replacement is rarely cheaper in practice.

This is where supplier experience matters. Teams who can support verification, adapt to site conditions, and maintain consistency reduce friction later.

The difference shows up over years, not weeks.

A Practical Note on Shenzhen XinHe Lighting Optoelectronics Co., Ltd

Shenzhen XinHe Lighting Optoelectronics Co., Ltd has been active in outdoor LED lighting projects since 2004, with a focus on point light sources, grid-based systems, and architectural applications.

Rather than positioning products in isolation, the company supports projects through design coordination, budgeting input, product delivery, and on-site technical guidance. This approach reflects an understanding that outdoor lighting performance depends as much on context as on components.

With established production systems and certified quality and environmental management frameworks, XinHe Lighting works in environments where long operating cycles and consistency matter more than short-term gains.

Заключение

Outdoor LED lighting doesn’t usually fail loudly. It fades, shifts, or becomes inconvenient.

The projects that age well tend to share one habit: decisions were made early, with an understanding of how light behaves over time, not just how it looks on opening night.

Good lighting often goes unnoticed. That’s usually a sign it was done right.

FAQs

How early should outdoor LED lighting be considered in a project?

Earlier than most teams expect. Once structure and circulation are fixed, lighting options narrow quickly.

Is brighter outdoor lighting always safer?

Not necessarily. Excessive brightness can reduce contrast and create glare, especially in pedestrian areas.

Are point light sources practical for large buildings?

They can be, particularly when used to handle detail while other fixtures manage broader coverage.

Why do outdoor LED fixtures sometimes fail despite good specifications?

Installation context, thermal buildup, and moisture pathways often matter more than listed ratings.

What usually causes uneven appearance across large facades?

Spacing decisions and batch consistency are common factors, especially in long installations.