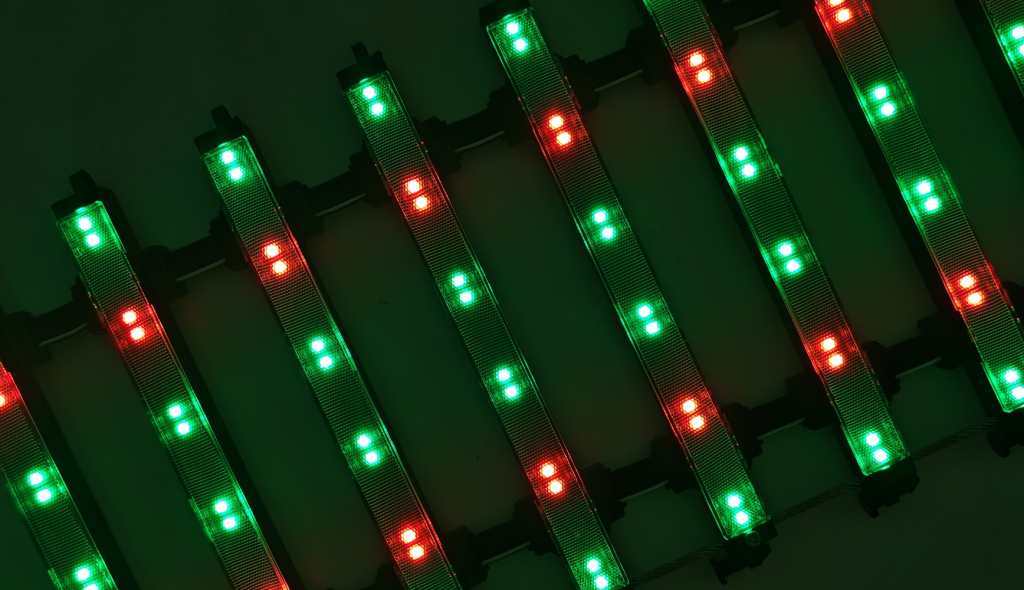

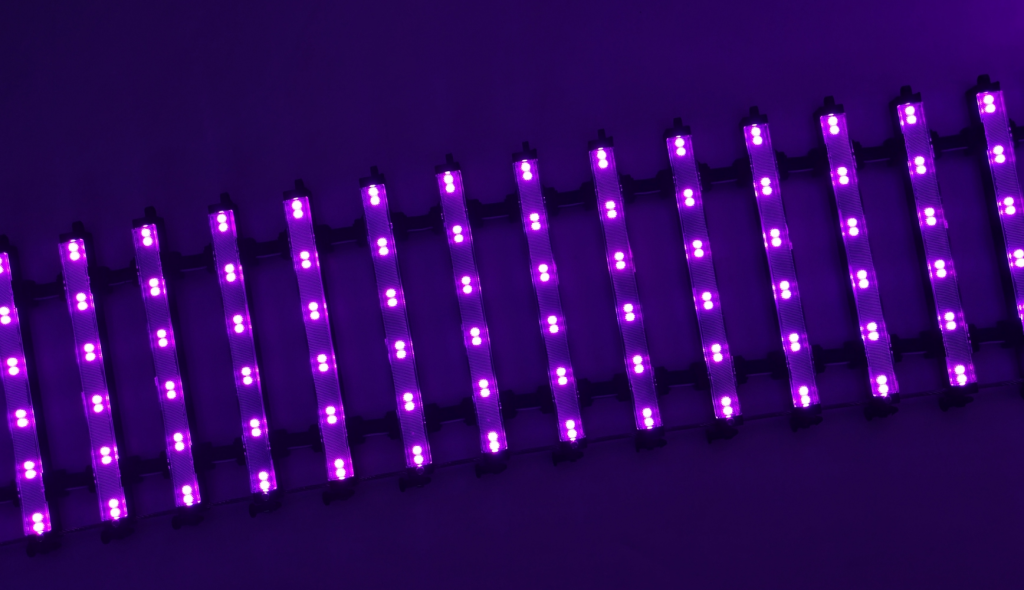

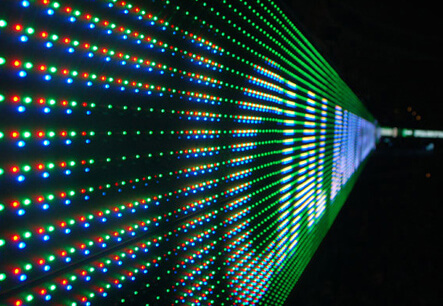

Picture a bustling city skyline at night, where towering glass facades glow with intricate patterns from LED grid screens. These displays don’t just light up buildings—they withstand relentless rain, dust, and temperature swings. Yet, for buyers in architectural lighting projects, the real worry comes when high power LED in sealed fixtures start to falter under heat buildup. That slow dimming, known as thermal decay in LEDs, can slash service life from promised 50,000 hours down to half, turning a smart investment into costly replacements. In outdoor setups, where enclosures seal against weather, managing heat isn’t optional; it’s the difference between vibrant, long-lasting illumination and frequent downtime.

This deep dive explores how effective thermal management in outdoor LED lighting tackles these issues head-on. We’ll look at materials that pull heat away efficiently, designs that promote airflow even in tight spaces, and drivers that keep everything stable. Drawing from industry experience, like those massive urban installations where LEDs run non-stop, the goal here is to arm procurement teams and engineers with insights that make choosing the right fixtures straightforward. After all, in competitive bids for landscape or advertising projects, understanding heat impact on LED lifespan means picking products that deliver value over years, not months.

The Challenge of Thermal Decay in LEDs

Thermal decay in LEDs happens when excess heat builds up at the junction—the tiny spot where light is born. In outdoor environments, high-power LED cooling in enclosures becomes tricky because sealed designs trap warmth, leading to faster degradation. Think about a grid screen on a hotel facade: during a hot summer day, ambient temperatures climb, and the LEDs generate their own heat from constant operation. If not handled well, this leads to a drop in brightness and color accuracy over time.

Data from real-world tests shows the stakes. A study published in the Journal of Applied Physics (2015) found that for every 10°C increase in junction temperature, LED efficiency drops by up to 20%, and service life halves in some cases. That’s a big hit for B2B applications like traffic hubs or enterprise exhibit halls, where downtime for replacements disrupts operations. Factors affecting LED service life include not just the initial build but ongoing exposure—sealed LED fixtures heat issues amplify this, as air can’t circulate freely to carry heat away.

In practice, we’ve seen projects where poor heat dissipation in LED lights caused early failures. For instance, in a coastal advertising setup, salt air combined with trapped heat corroded components, cutting lifespan short. The pain point is clear: without solid strategies, outdoor LED durability and heat become enemies, forcing buyers to overspend on frequent upgrades. Addressing this starts with recognizing how sealed environment LED thermal control can turn the tide, keeping lights bright and reliable through seasons of use.

Exploring Heat Dissipation in LED Lights Through Materials

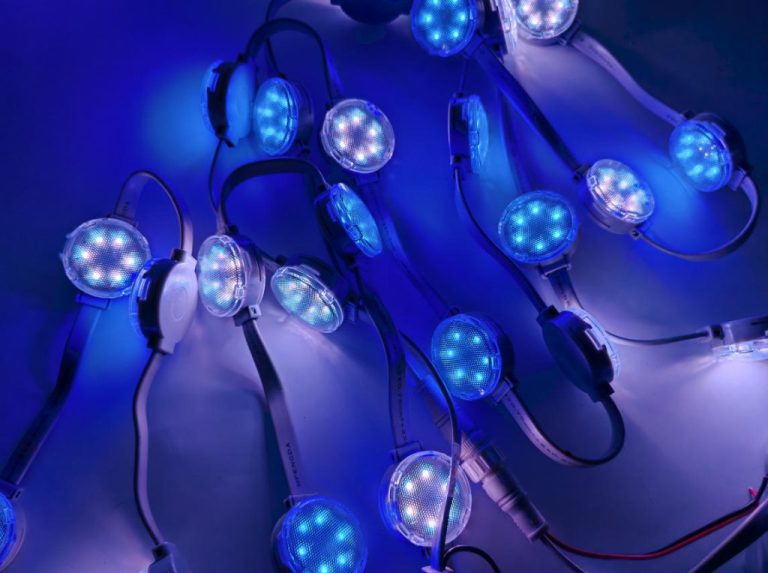

Materials play a starring role in battling heat. Solid choices like aluminum alloys or specialized polycarbonates act as silent guardians, pulling warmth from the LED chip and spreading it out. In high power LED heat dissipation, these aren’t just passive parts—they actively fight thermal buildup. Aluminum, with its high thermal conductivity around 200 W/m·K, excels in wicking heat away quickly, much like how a metal spoon draws warmth from hot coffee.

Consider laminate HPL tabletops in furniture analogies, but here it’s about LED heat sinks molded into the fixture body. These surfaces maximize contact, ensuring heat flows outward rather than lingering. A report from the IEEE Transactions on Electron Devices (2018) notes that effective materials can extend LED fixture lifespan optimization by 30%, by keeping junctions below 85°C. For outdoor use, where dust and moisture add challenges, durable coatings on these materials prevent corrosion while maintaining efficiency.

From industry angles, projects like illuminating glass curtain walls show this in action. A veneer-like layer on the base might seem thin, but when engineered right, it handles the load. LED light decay causes often trace back to mismatched materials that can’t cope with power demands—switch to robust ones, and suddenly, service life stretches. Buyers eyeing long-term value find this crucial; it means fewer calls for repairs and more consistent performance in demanding spots like airports or malls.

Innovative Structure Design for Effective LED Heat Sinks

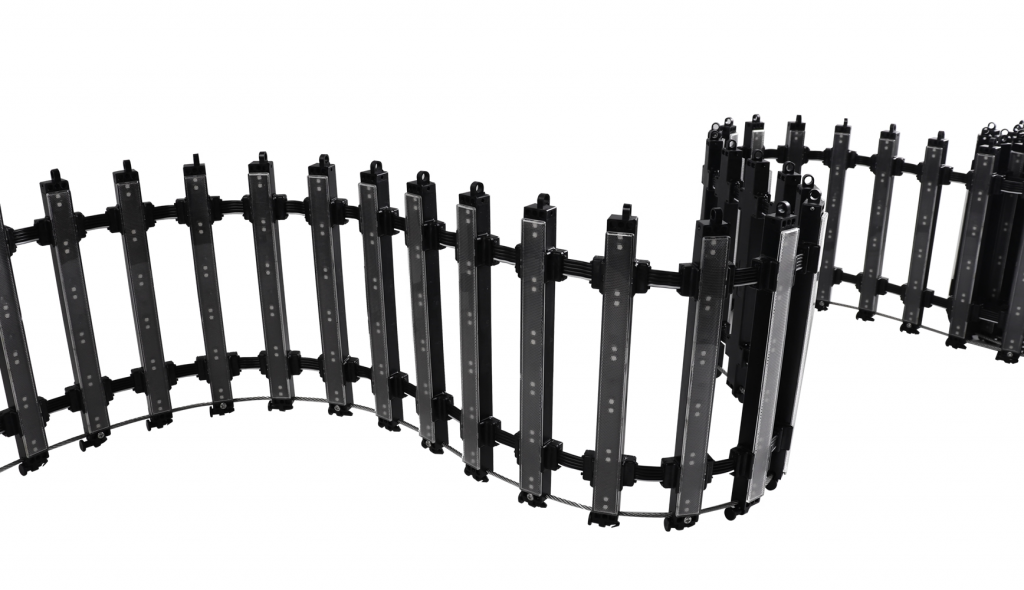

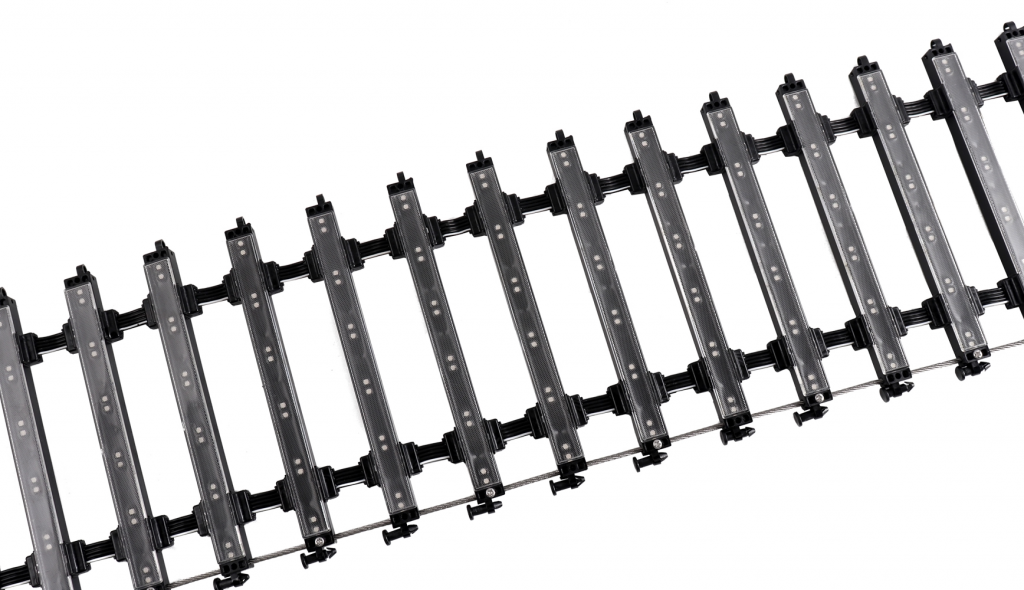

Structure isn’t just about looks—it’s the backbone for LED thermal management strategies. Clever designs incorporate vents or fins that encourage natural convection, even in tight, sealed spots. Take a modular setup where individual units snap together; this allows heat to escape through gaps without compromising weather resistance. In outdoor LED lighting heat management, such approaches mean the difference between a fixture that overheats after hours and one that runs cool through the night.

High-power LED cooling in enclosures benefits from these innovations. Fins increase surface area for dissipation, similar to how radiators work in cars, pulling heat out efficiently. According to research in Optics Express (2020), optimized fin designs can reduce temperature by 15-20°C, directly boosting heat impact on LED lifespan. For grid screens or point lights in urban settings, this translates to structures that handle high brightness without fading fast.

Real scenarios highlight the edge. Imagine a virtual reality exhibit where LEDs form dynamic patterns—the design must vent heat to avoid blur from decay. LED heat dissipation techniques like these ensure stability, with drivers tuned to pulse power without spikes. Procurement pros appreciate how such builds cut maintenance, making them ideal for large-scale buys where reliability counts most.

Strategies for LED Lifespan Factors and Optimization

Optimizing lifespan boils down to smart strategies that address core weaknesses. Stable drivers are key; they regulate current to prevent surges that amp up heat. In sealed setups, pairing this with materials that conduct well creates a system where thermal decay in LEDs stays minimal. Industry data from the Lighting Research Center (2019) shows consistent driving can push lifespan past 70,000 hours, far beyond standard claims.

Factors affecting LED service life include environmental tweaks, like positioning fixtures to catch breezes. For outdoor durability, adding phase-change materials that absorb excess heat during peaks helps smooth things out. We’ve noted in landscape projects how this flattens temperature curves, avoiding the sharp drops in brightness that plague lesser designs.

B2B buyers can apply these by checking specs for driver efficiency—look for ratings above 90%. Combining with regular checks ensures long-term glow. In essence, these steps turn potential pitfalls into strengths, delivering lights that shine reliably for years.

About Shenzhen XinHe Lighting Optoelectronics Co., Ltd.

Shenzhen XinHe Lighting Optoelectronics Co., Ltd., founded in 2004, stands as a pioneer in LED innovation, specializing in point light sources and grid screens with proprietary technology. Based in Shenzhen, China, the company delivers comprehensive solutions for architectural and advertising lighting, from design to on-site support. With certifications like ISO 9001 and ISO 14001, plus over 80 patents under the “Bean” brand, XinHe emphasizes quality and sustainability. Their products, like flexible transparent screens and high-protection grid displays, excel in global projects, blending advanced R&D with cost-effective manufacturing to meet demanding outdoor needs.

Заключение

Mastering thermal management in outdoor LED lighting means conquering heat dissipation challenges to secure longer service life. Through smart materials, innovative designs, and stable drivers, fixtures withstand harsh conditions while maintaining peak performance. For procurement teams, this knowledge translates to wiser choices that minimize costs and maximize impact. Exploring these elements reveals how targeted approaches solve real-world issues, paving the way for brighter, more enduring installations.

FAQs

What role does heat dissipation in LED lights play in extending LED service life?

Heat dissipation in LED lights directly combats thermal decay, ensuring junctions stay cool to preserve brightness over time. In outdoor setups, effective methods like aluminum conduction can add thousands of hours to operation, as seen in grid screen applications where steady performance is key.

How do sealed LED fixtures heat issues affect high power LED heat dissipation?

Sealed LED fixtures heat issues trap warmth, accelerating decay unless designs incorporate vents or conductive paths. For high power models, this means prioritizing materials that wick heat efficiently, preventing the 20-30% efficiency loss noted in industry tests.

Why is thermal management in outdoor LED lighting crucial for LED lifespan factors?

Thermal management in outdoor LED lighting addresses core LED lifespan factors like temperature spikes, which can halve service hours. By focusing on stable drivers and structures, it maintains consistent output, vital for projects facing weather extremes.

Can innovative structure design improve outdoor LED durability and heat control?

Yes, innovative structure design enhances outdoor LED durability and heat by maximizing airflow in enclosures. Features like fins reduce thermal buildup, supporting longer runs in demanding environments without compromising protection.

What strategies help with LED fixture lifespan optimization in sealed environments?

LED fixture lifespan optimization in sealed environments involves combining robust materials with efficient drivers to flatten heat curves. This approach counters decay causes, delivering reliable performance for B2B needs in landscape lighting.