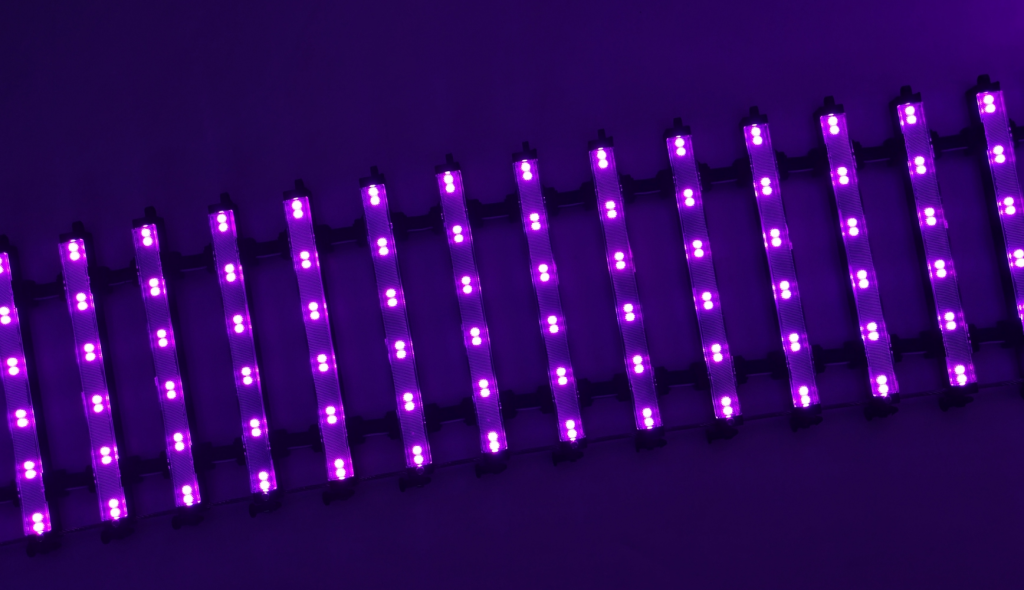

Picture this: a bustling city square at dusk, where a massive LED mesh screen wraps around a sleek glass building, pulsing with vibrant ads that draw crowds like moths to a flame. It’s not just eye candy—it’s a workhorse, running non-stop through rain, wind, and the occasional pigeon detour. But here’s the kicker: that screen didn’t get there by magic. Getting it up and keeping it humming takes smart planning. If you’re knee-deep in outfitting a storefront, stadium, or landmark with one of these bad boys, you’re in the right spot. We’ll dive into practical installation and maintenance tips that keep your LED mesh screen durable and long-lasting, so it pays off for years without turning into a headache.

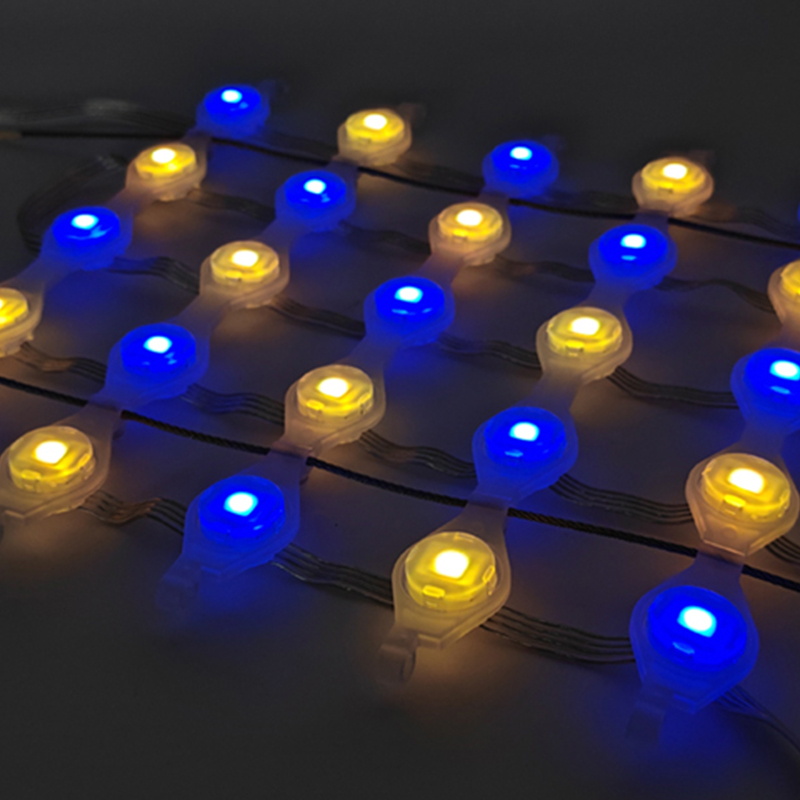

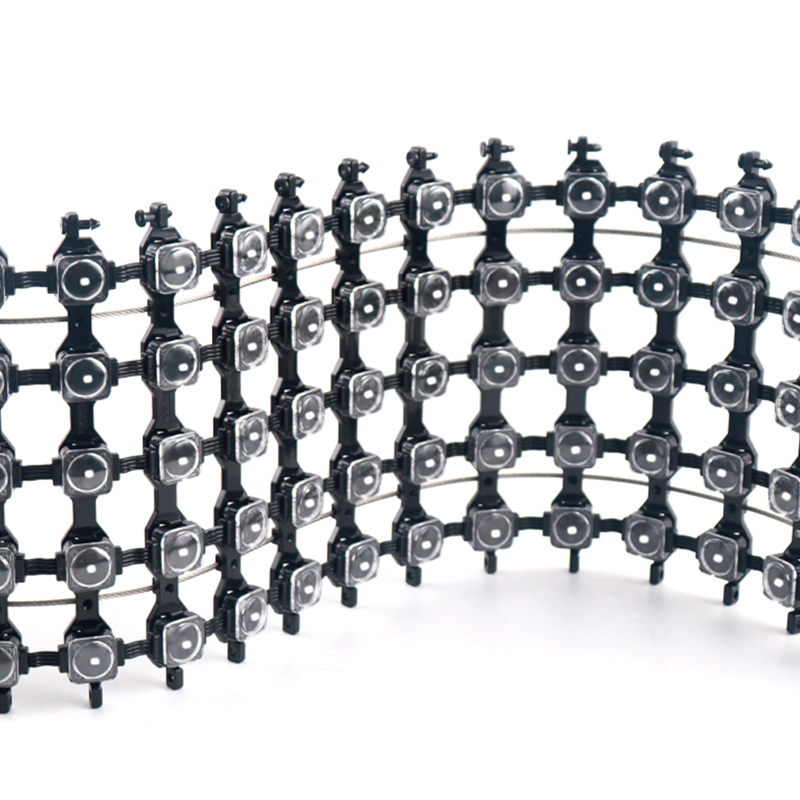

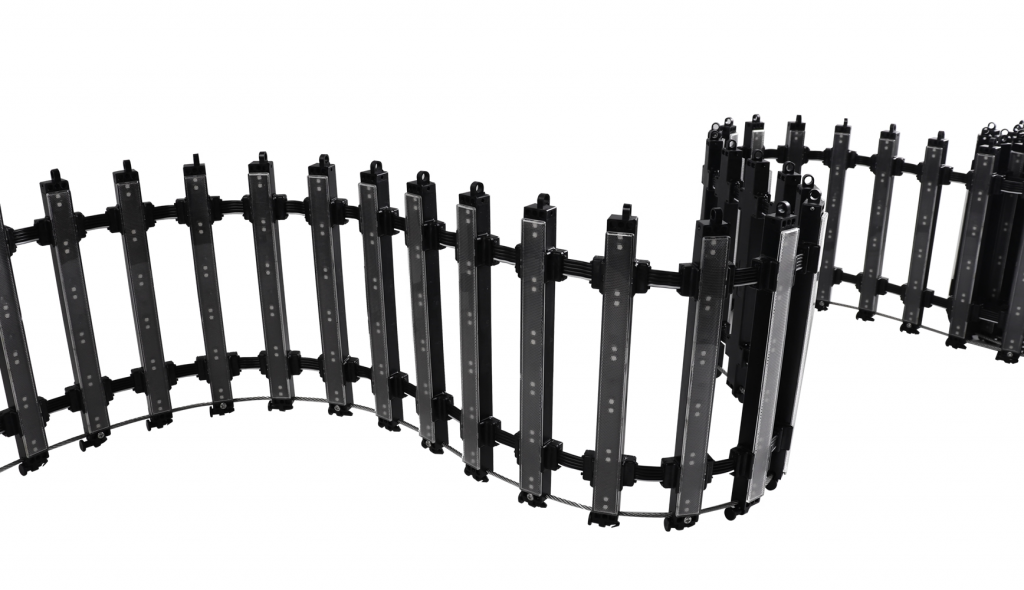

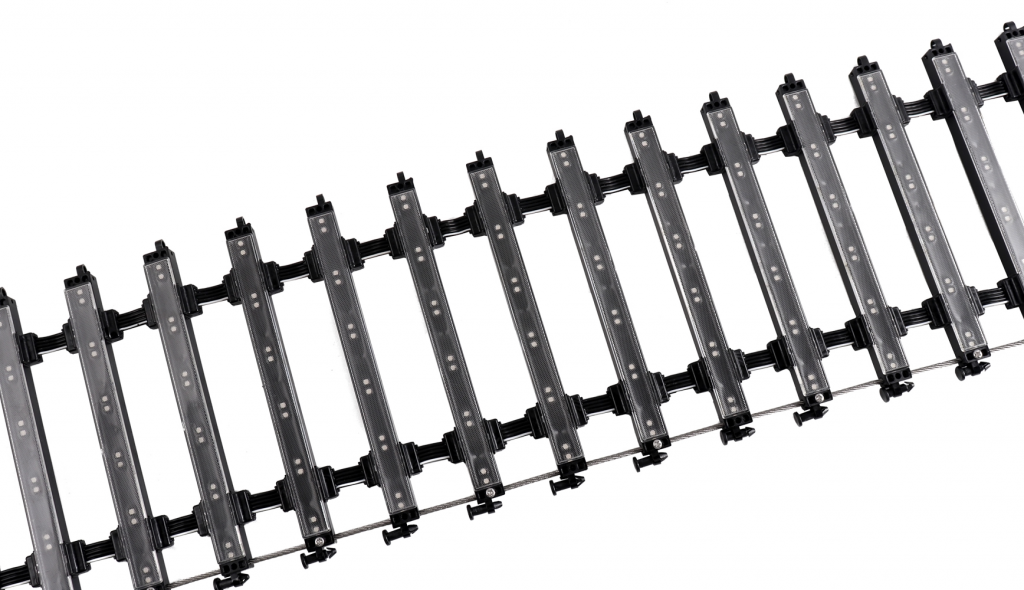

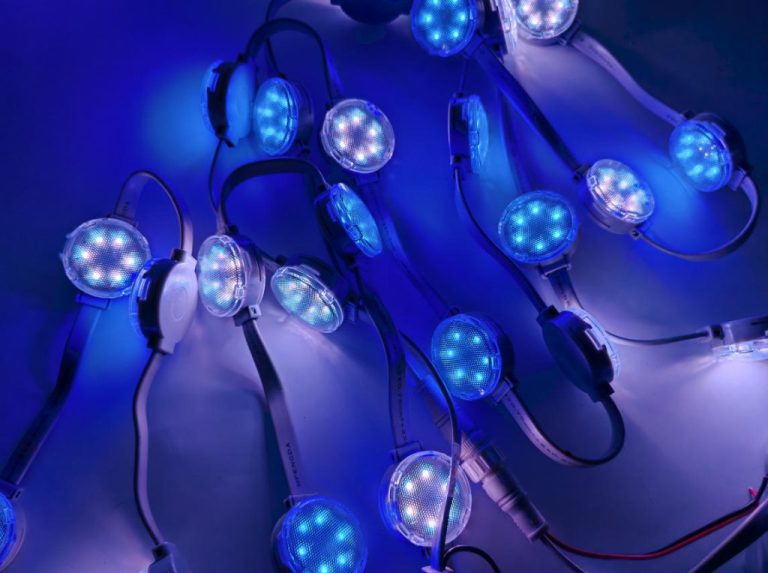

LED mesh screens aren’t your grandpa’s neon signs. They’re flexible grids of pixels that bend around curves, breathe easy with built-in ventilation, and shrug off the elements. Think of them as the Swiss Army knife of digital displays—perfect for wrapping facades or staging events. What sets the durable ones apart? It’s all in the build: IP67 waterproofing that laughs at downpours, self-cooling tech that wards off burnout, and modules you can swap out faster than changing a flat tire. In my line of work, I’ve seen setups last over five years in coastal spots where salt air chews up lesser gear. Stick with these tips, and you’ll dodge the drama.

Getting the Lay of the Land: Why Proper Setup Matters

Before you even unpack the crates, pause. Rushing installation is like building a house on sand—looks fine until the storm hits. A solid prep phase cuts risks and stretches your screen’s life. Industry stats show that 70% of early failures trace back to skimpy site checks or mismatched gear. We’re talking about screens that can span hundreds of square feet, so yeah, it pays to think ahead.

Start with the basics: scout your spot. Is it a flat wall, a curved atrium, or some wild steel skeleton? Measure twice—pixel pitch matters here. A 50mm spacing works great for distant views, like on a high-rise, but bump it to 83mm if folks are up close at an event. Factor in power draw too; these screens guzzle less than rigid panels, but a 100W max per module adds up quick. Oh, and don’t forget the wind—coastal installs need extra anchoring to handle gusts up to 30 mph without flexing like a sail.

Safety first, always. Helmets, harnesses for heights, and grounded tools aren’t optional. I’ve been on jobs where a loose wire sparked a shutdown; nobody wants that smoke show.

Tools and Materials You’ll Need

Grab the right kit, and half the battle’s won. Here’s a quick rundown—no fluff, just what works.

| Category | Essentials | Why It Counts |

| Mounting Hardware | Bolt splicing steel wires, anchors (M8 size), clamps | Locks modules tight without drilling holes everywhere; saves hours on big jobs. |

| Power & Cabling | DC12V/24V supplies, DMX512 controllers, weatherproof cables | Keeps juice flowing steady—overloads fry pixels fast. |

| Testing Gear | Multimeter, pixel tester app, ladder/scaffolding | Spots bad connections before they bite; trust me, debugging at 20 feet up sucks. |

| Safety Bits | Gloves, eye protection, voltage tester | Basics that keep you in one piece—I’ve skipped ’em once, regretted it twice. |

Stock up on extras; Murphy’s law loves running out mid-hang.

Step-by-Step: Nailing the Installation

Alright, crates open—let’s mount this thing. The beauty of a good LED mesh screen? It’s modular, like Lego for pros. Bolt-spliced steel wires mean you snap sections together without a PhD in engineering. Aim for a team of three: one on ground control, two up top. On a 10×5 meter facade job last summer, we knocked it out in under four hours flat. Here’s how.

First, map your grid. Lay out modules on the ground to match your design—say, 20×20 pixels for tight spacing. Connect power and data lines daisy-chain style; DMX512 keeps signals crisp over distance. Pro tip: label cables. You’ll thank yourself when troubleshooting later.

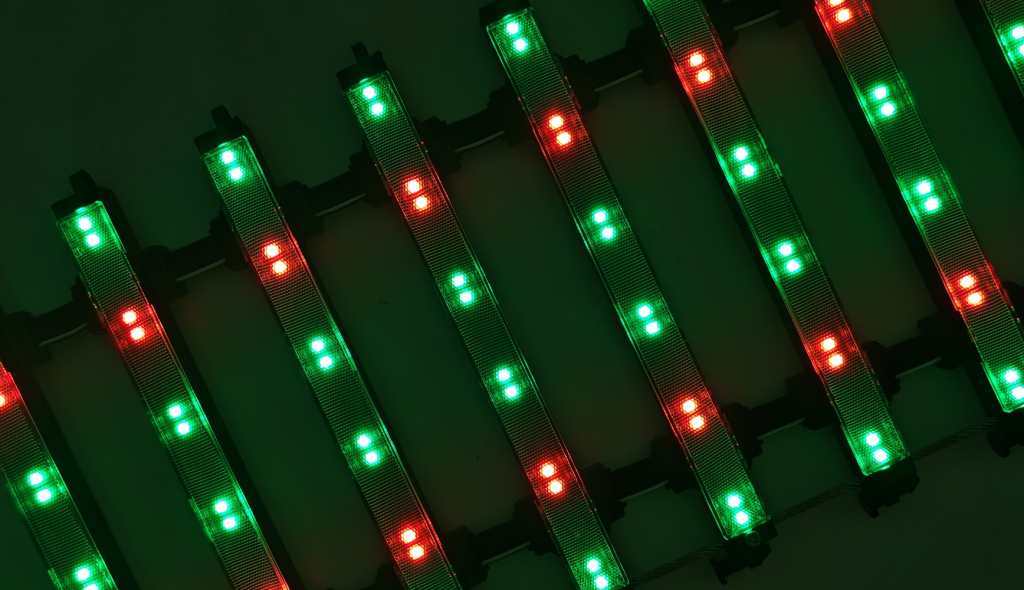

Hoist ’em up. Start from the bottom for stability—anchor to the structure with those steel wires, torquing bolts to 15 Nm. For curves, like on a lobby arch, flex the mesh gently; its transparency lets light through without blocking views inside. Secure edges with clamps every meter to fight sag. Power on in sections—test each module’s glow before full commit. If a pixel flickers, swap it now; bad points propagate like gossip.

Weather’s a wildcard. In humid spots, dry everything post-rain before firing up. And for outdoor beasts, angle slightly downward to shed water—I’ve seen pooled moisture short out seals otherwise.

Tailored Tweaks for XinHe-Style Screens

Screens built like tanks, with self-heat dissipation and IK10 impact resistance, shine here. Their lightweight vibe—under 3kg per panel—means less strain on rigging. For salt-spray zones, like seaside billboards, the corrosion-proof coating holds up; one install in a harbor town ran three years spotless. Just ensure your voltage matches—DC12V for most, 24V if pushing high density.

Keeping It Running: Maintenance That Sticks

Installation’s the sprint; maintenance is the marathon. These screens boast over 30,000 hours of life, but neglect ’em, and you’re looking at dim spots by year two. The goal? Simple routines that catch issues early. Think of it as oil changes for your display—boring, but it keeps the engine purring.

Daily: Eyeball it. Walk the perimeter at dawn; uneven brightness screams loose connection. Wipe dust with a microfiber cloth—dry, no chemicals. Harsh cleaners strip seals, and boom, water sneaks in.

Weekly: Dive deeper. Power cycle the system—off for 30 seconds resets glitches. Check cables for frays; UV eats insulation over time. In dusty venues like warehouses, a soft brush clears vents. Data point: Facilities that log these checks see 25% fewer callouts.

Monthly deep clean calls for more. Unplug, then hose gently—IP67 means it handles low-pressure sprays, but aim away from joints. Dry thoroughly; fans speed it if you’re impatient. Inspect modules for cracks; that V-0 flame retardant is tough, but impacts ding ’em.

Your Go-To Maintenance Schedule

Structure it like this, and it becomes habit.

- Daily Quick Scan: Visual patrol, dust wipe (5 mins).

- Weekly Check-In: Cable tug-test, power reset (15 mins).

- Monthly Overhaul: Gentle wash, module swap if needed (1-2 hours).

- Quarterly Pro Review: Full voltage test, firmware update (hire out if no tools).

Track it in a log—apps like Fieldwire make it painless. One quirky note: birds love perching on these; netting saved a church steeple install from, uh, unwanted decor.

Spotting Trouble Before It Snowballs

Even the toughest screens throw curveballs. Pixels out? Could be a bad driver—trace the chain with a tester. Dim overall? Voltage drop; shorten runs or add boosters. Flickering in storms? Grounding issue—stake that earth rod deeper.

Heat’s the silent killer. If modules hit 60°C, amp ventilation; self-dissipating designs help, but overcrowd ’em, and nope. Salt buildup in coastal gigs? Rinse quarterly—resistance testing shows these hold up, but grime lies. And software glitches? Update DMX firmware; I’ve fixed “ghosting” that way more than once over a coffee break.

Real talk: 80% of fixes are 20% effort if you catch ’em fast. Budget 5% of install cost yearly for upkeep—pays dividends.

Boosting Longevity: Pro Hacks for the Win

Want your screen outlasting the building? Layer on smarts. Site it south-facing for even sun exposure—fades less. Use surge protectors; power spikes toast controllers. And cycle content—static images burn pixels faster, per burn-in studies.

Data backs it: Units with routine checks average 40,000+ hours. In a Vegas casino wrap, one ran seven years with zero swaps. Mix in modular swaps; front-access panels mean no scaffolding drama. Environment tweaks, like shade cloths in deserts, drop temps 10°C.

It’s not rocket science—just consistent care. Throw in some creativity, like syncing lights to events, and your display becomes a star, not a sidelight.

Why XinHe Stands Out as Your LED Mesh Screen Go-To

When you’re scouting suppliers, XinHe Optoelectronics cuts through the noise. Based in Shenzhen since 2004, they’ve poured two decades into crafting point light sources and mesh screens under the trusted “Bean” banner. Their factory spans 6,000 square meters, buzzing with 250 pros who churn out IP67-sealed, self-cooling wonders rated for -20°C to 60°C extremes. What grabs me? The patents—like bolt-spliced fixes that slash install time—and ODM tweaks for your exact vibe, from harbor-proof coatings to event-ready flex. Annual sales top 20 million, with creds like ISO9001 quality seals proving they deliver reliable, no-fuss gear. If durability’s your jam, XinHe’s the partner that gets projects lit without the lights-out surprises.

Wrapping It Up: Light the Way Forward

There you have it—straight-shooting advice to get your LED mesh screen mounted right and running forever. From that first bolt twist to the routine rinse, every step builds toward a display that’s not just tough, but a traffic magnet. Skip the shortcuts; invest the time, and watch your investment glow brighter than the competition. Whether it’s jazzing a mall or branding a bridge, these tips turn potential pitfalls into smooth sailing.

Frequently Asked Questions

How often should I perform installation and maintenance tips to ensure my LED mesh screen stays durable and long-lasting?

Spot on—regular checks are key. Hit a quick daily visual, weekly cable tug, and monthly wash. That rhythm keeps things humming past 30,000 hours without sweat.

What makes LED mesh screens from suppliers like XinHe so good at handling tough weather for long-lasting performance?

It’s the build: IP67 seals block water like a champ, plus salt-spray resistance for coastal beats. Pair that with self-heat dissipation, and you’ve got gear that shrugs off storms—I’ve seen ’em thrive in monsoons.

Can I install a durable LED mesh screen on a curved surface, and what maintenance tips help it last?

Absolutely—flexible modules hug curves easy with bolt splices. For upkeep, just ensure even tension during setup, then monthly inspections catch any sag. Keeps it looking sharp for years.

What’s the biggest mistake folks make with installation and maintenance tips for long-lasting LED mesh screens?

Rushing the ground test—pixels misaligned early means headaches later. Slow down, label those cables, and you’re golden. Trust me, it saves more time than it costs.

How does proper ventilation factor into maintenance tips for durable and long-lasting LED mesh screens?

Huge—built-in transparency lets air flow free, but dust clogs kill it. Weekly brushes and avoiding cramped spots keep temps low, stretching life way beyond the basics.