Some DMX512 facade pixel lights aren’t responding: causes & fixes is the kind of search you make when the job is already live, the building is dark in spots, and somebody is asking why “only that section” won’t play along. In facade projects, partial non-response is rarely random. It usually traces back to a predictable handful of causes: addressing and channel footprint mistakes, a DMX physical-layer problem that shows up only on long outdoor runs, power drop that resets decoders, or weather-driven connection failures that come and go. This guide is written for the people who actually have to make it work on-site—integrators, contractors, and maintenance teams—using the same logic you’d use in the field, not just in a lab. For an overview of the product families typically used in media facades and outline lighting, you can start at the Shenzhen XinHe Lighting official website.

Answer: Some DMX512 facade pixel lights aren’t responding: causes & fixes

When some DMX512 facade pixel lights don’t respond, the fastest reliable fix path is to separate “no light output” from “lights on but not controlled,” then work from the last known-good point outward until the failure reproduces. Most partial outages come from one of four buckets. The first is configuration: wrong start address, wrong DMX mode, wrong channel footprint, or a universe boundary mistake that leaves later pixels reading empty data. The second is signal integrity: a long run, poor shielding, a topology that behaves like a star, missing termination, or noise coupling from nearby power lines—often fine at first, then unstable at night or after a weather swing. The third is power delivery: the supply looks healthy at the cabinet, but far-end voltage droops during bright content, causing decoders to reset or latch up. The fourth is the outdoor layer: a connector, splice, or cable route that is water-stressed, corroded, or mechanically strained, creating an intermittent open circuit. Once you approach it in that order, you stop guessing and start fixing.

What “Not Responding” Really Means on a Building Facade

On a facade, “not responding” can mean three different things, and treating them as the same problem wastes hours. If pixels are completely dark, you may be dealing with power loss, polarity issues, or a failed node that also interrupts pass-through. If pixels are lit but frozen on one color, the fixture may be powered but not receiving valid DMX data, or it may be in the wrong control mode. If only the first part of a run responds and the rest stays dead, that’s usually a break in the chain—either a physical open circuit, a failed pass-through at a node/decoder, or a branching wiring method that doesn’t behave on long outdoor runs the way it did on the bench.

A simple on-site clue is consistency. If the same section fails every time, you likely have a fixed address boundary or a fixed physical break. If the failure moves around, shows up only after rain, or appears only during bright scenes, you’re almost certainly looking at power drop or an outdoor connection that is intermittently compromised.

Confirm the Basics First: Universe, Mode, and Channel Footprint

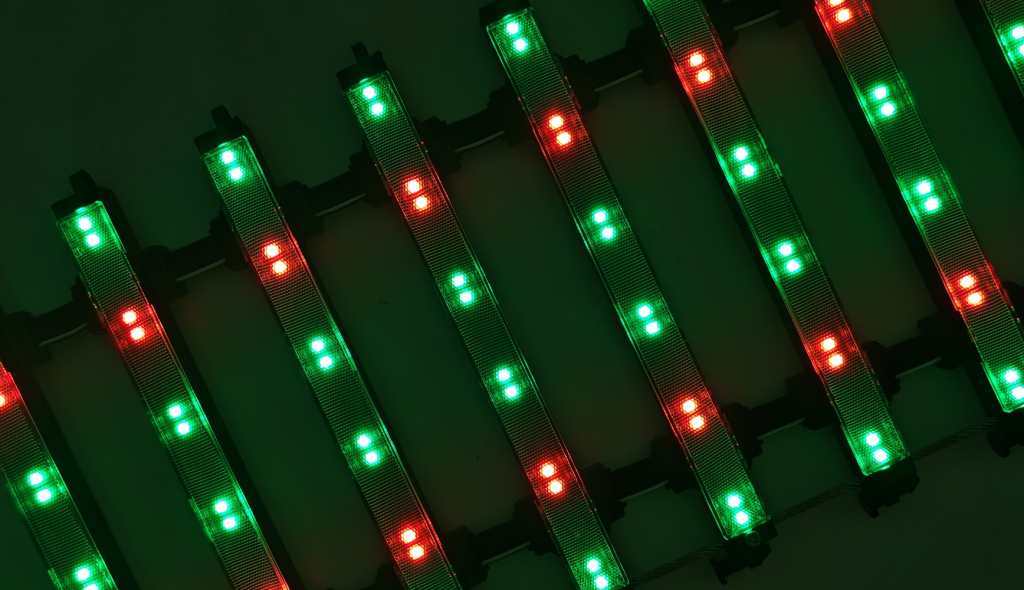

DMX512 is straightforward until pixels enter the picture, because pixel products come in different personalities. One fixture might be RGB (three channels), another RGBW (four), and another might bundle multiple pixels behind a single decoder footprint. On a facade, it’s common to see a section “go dead” right where someone unknowingly crossed a universe boundary or changed a fixture mode mid-run.

This is where you want to be painfully literal. Verify the controller output format, confirm the intended DMX mode at the fixture or decoder, and confirm the start address scheme matches the real channel footprint. If you designed for RGB and one section is set to RGBW, every pixel downstream can appear “not responding” because it’s actually reading the wrong channels. The fixture isn’t broken. It’s just listening to the wrong part of the stream.

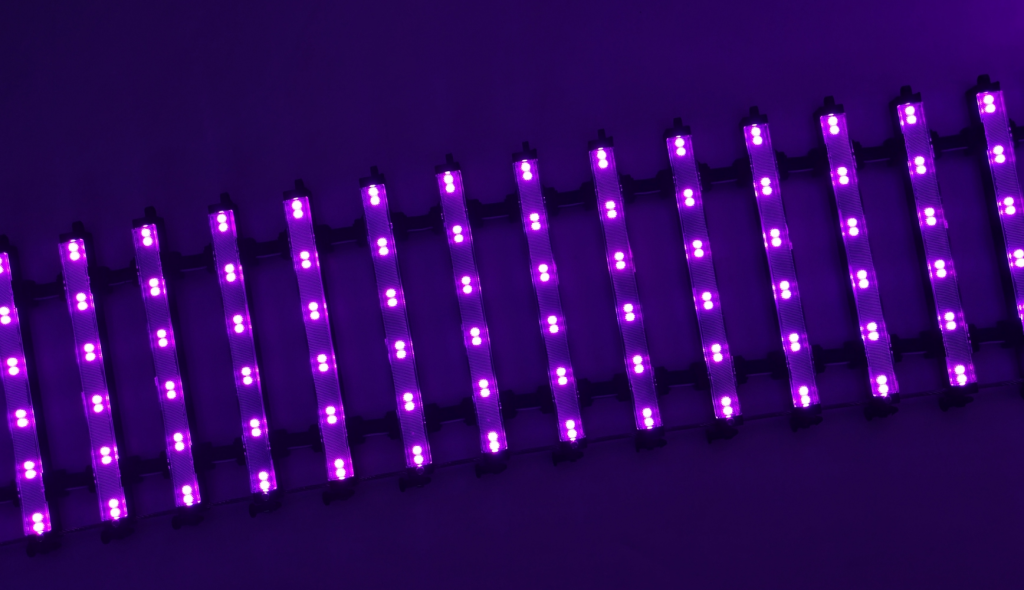

If your site uses DMX pixel point lights for outlines or signage, it also helps to standardize on a consistent family of fixtures so footprints and addressing behavior don’t vary by zone. Shenzhen XinHe Lighting Optoelectronics Co., Ltd manufactures DMX-capable point light products for building and landscape applications, with models that typically run on low-voltage DC and are designed for outdoor installation, which makes it easier to keep projects consistent across elevations and phases. You can see the range on the DMX512 facade pixel products.

The Field Method That Actually Works: Segment-by-Segment Isolation

The fastest troubleshooting tool on a facade is not a new controller. It’s a disciplined isolation routine. Start at the last pixel that responds reliably, then test the next segment downstream until the failure returns. This is how you find the break without getting distracted by everything that “might” be wrong.

In practice, this often looks like a late-night service call where the first 18 meters behave and the remaining 12 meters don’t. Instead of replacing random pixels, you temporarily bypass the next connection, or you disconnect downstream and test only the upstream section. Once you know exactly which connector, splice, or fixture marks the start of the failure, the fix becomes far more obvious: that point is where power, data, or continuity stops being healthy.

A good technician also watches for “half-working” behavior. Sometimes a section responds at low brightness but collapses at full white. Sometimes it responds when the wind is calm but fails when the cable moves. Those clues are gold. They tell you whether you’re dealing with voltage drop, mechanical strain, or a noisy DMX line that’s barely hanging on.

DMX512 Physical-Layer Problems That Cause Partial Non-Response

On paper, DMX is robust. On a real building, it’s a long cable run, routed around metal, near power feeds, exposed to EMI, and sometimes branched because the architecture is messy. That’s where partial non-response shows up.

If the DMX line is built with the wrong cable type or poor shielding, you can get a situation where the first part of the chain responds and the rest becomes unreliable, especially when the run length grows. If the topology behaves like a star, signal reflections and impedance mismatches can create “dead zones” that look like fixture failure but are actually data corruption. Missing or incorrect termination can also contribute to this. Facades are particularly sensitive because long vertical drops and horizontal traverses create enough distance for reflections to matter.

Another common facade pattern is noise coupling. When DMX is routed alongside mains power or near high-current LED power lines, bursts of noise can ride into the data path. The effect can be intermittent non-response, random freezing, or whole sections ignoring commands while others behave normally. The fix is usually a combination of better routing practices, proper shielding, and a topology that is designed for long outdoor runs rather than convenience.

Power Problems That Look Like DMX Problems

This is where many “top results” online stay too shallow, because they focus on DMX settings and ignore the fact that facade pixel systems are also power distribution systems.

A typical DMX512 facade pixel point light is low-voltage DC—commonly DC12V—because it’s practical for installation and maintenance. But low voltage means voltage drop becomes a real limiter. You can have a perfect DMX signal and still have pixels not respond if the decoder is browning out. It doesn’t always go completely dark, either. It may light but stop accepting commands, reset repeatedly, or fall into a weird state that looks like a data issue.

The key measurement is the voltage at the far end under real load. If your controller is running bright content, the current draw rises. A supply that reads 12.0V at the cabinet might be delivering 10.6V at the last node after cable losses and connector resistance. That’s enough to cause misbehavior in many systems, especially when temperature shifts and resistance changes. If you’ve ever seen a facade that works during commissioning and then fails during the first full-bright show, you’ve likely seen this exact effect.

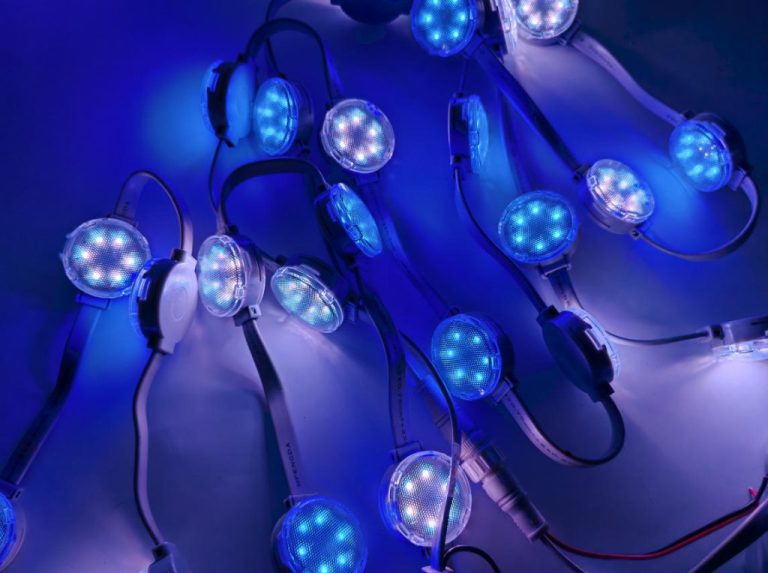

Shenzhen XinHe Lighting’s outdoor point light offerings emphasize outdoor protection and low-voltage operation, and product specifications commonly list DC12V operation, IP67 protection, and operating temperatures suited to outdoor projects, which aligns with the real constraints of facade power distribution. The important thing, though, is design discipline: power zoning, adequate conductor sizing, and injection strategies that keep voltage stable where it matters.

Outdoor Installation Failures: Water, Corrosion, and Mechanical Stress

A facade is not a clean room. Cables flex, connectors sit in water paths, UV and temperature cycles work against seals, and small mechanical stresses add up. That reality produces a specific kind of failure: intermittent non-response that shows up “after weather,” “only on the windy side,” or “only in winter.”

Water ingress is the obvious culprit, but the real story is usually at the connector or splice. A connector can be technically IP-rated and still fail if it’s not seated properly, if strain relief is weak, or if the cable route forms a drip loop that guides water straight into the joint. Corrosion raises resistance, which reduces voltage at the load, which then creates non-response that looks like a DMX fault. That’s why outdoor troubleshooting often feels circular until you test both power and data at the same physical point.

Mechanical stress is another underappreciated trigger. Facade cables get pulled during installation, zip-tied too tightly, or routed over edges that slowly abrade the jacket. The failure may be a partial conductor break that carries enough current at first, then opens when temperature changes or the cable moves. When you see a section that comes back to life after you re-seat a connector, don’t stop there. That’s a symptom. The underlying mechanical condition may still be waiting to fail again.

Fixes That Stay Fixed: Design and Commissioning Practices

If you’re writing this blog to drive search traffic, you’re also writing it to earn trust. The most useful content doesn’t just fix tonight’s outage; it prevents the next one.

On new installations, start with documentation that matches the physical reality. A clean address map, a clear universe plan, and a wiring diagram that reflects where branches truly exist will save you from the midnight question: “Why does it stop right there?” Commission with worst-case content, not a gentle demo pattern. If it survives full-bright and high-motion content for a sustained period, it’s far more likely to survive real operation.

For long or complex facades, plan the DMX distribution like a network. Don’t let convenience create unstable topology. If the architecture demands branching, treat that as a design choice that may require distribution hardware and disciplined routing rather than improvised splices. On the power side, treat low-voltage DC distribution as a system with zones and margins, not a single supply with long tails.

If your project requires a custom form factor, non-standard mounting, specialized lensing, or a tailored wiring harness for faster installation, it’s worth involving the manufacturer early so the product design supports the commissioning plan rather than fighting it. Shenzhen XinHe Lighting provides customization and project support pathways that fit this reality; you can review options through the ODM/OEM customization services.

About Shenzhen XinHe Lighting Optoelectronics Co., Ltd

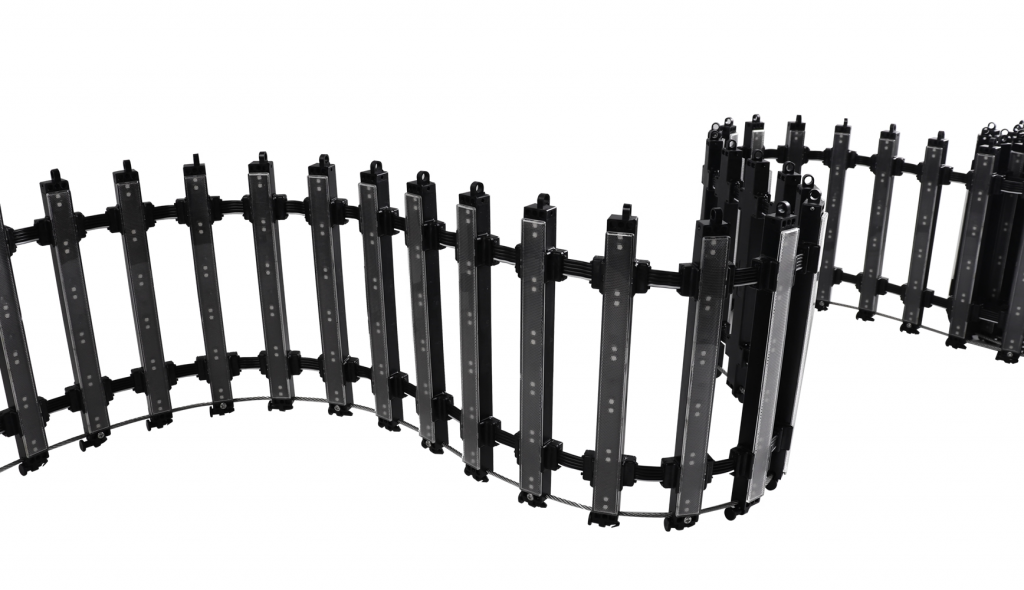

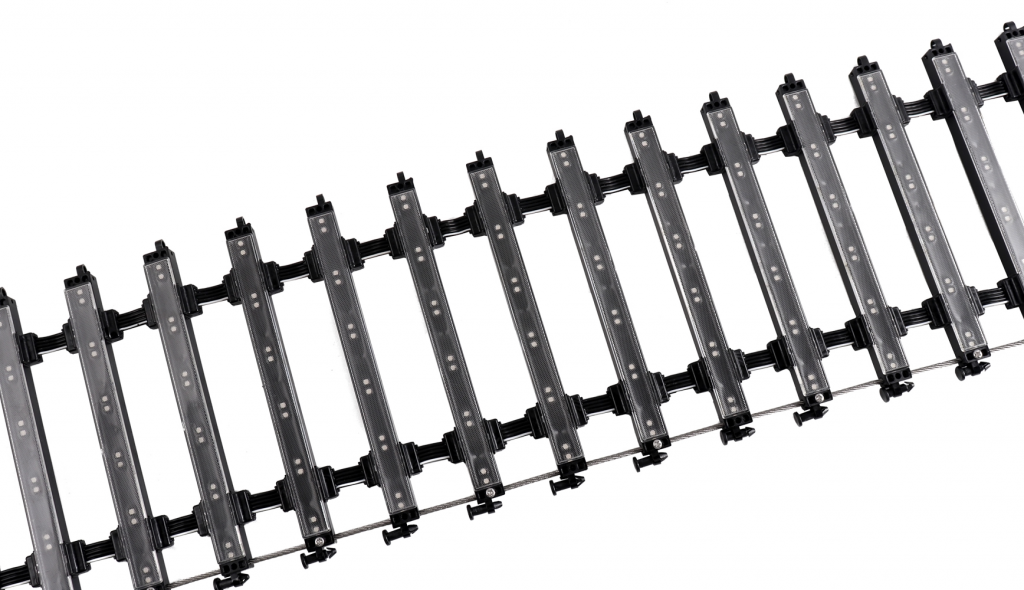

Shenzhen XinHe Lighting Optoelectronics Co., Ltd, established in 2004, has focused for years on the research, development, and application of LED point light sources and grid-screen systems used in architectural landscape and advertising lighting projects. The company’s product scope centers on facade-ready lighting hardware—such as point lights and mesh-style systems—paired with project-oriented support that can include scheme design, engineering budgeting, product supply, and on-site guidance. That combination matters in the facade world, because real projects don’t fail only due to product selection; they fail when system design, installation practice, and long-term maintenance realities don’t align. For a concise background and the company’s positioning in the LED facade segment, see About Shenzhen XinHe Lighting.

Conclusion

Some DMX512 facade pixel lights not responding is rarely a mystery once you treat the facade as a system. If lights are dark, prove power and continuity first. If lights are on but ignore control, confirm mode, addressing, and channel footprint before you touch wiring. If the chain dies halfway, isolate the break by rebuilding the run from the last known-good point. Then look at the two big facade realities that don’t show up in simple tutorials: long-run DMX physical-layer behavior and low-voltage power drop under real brightness loads. Finally, assume the outdoors is part of the circuit, because water paths, corrosion, and cable strain will eventually turn into intermittent outages unless the installation is hardened from day one.

FAQs

Why are some DMX512 facade pixel lights not responding after I set the address?

This often happens when the fixture mode or channel footprint doesn’t match your addressing plan. An RGBW mode where you assumed RGB, or a decoder personality that bundles pixels differently than expected, can shift channel alignment so downstream pixels appear dead even though they are receiving data. Reconfirm the fixture mode and channel footprint, then verify start addresses again with that footprint in mind.

Why does my DMX chain stop halfway and the rest of the facade pixels don’t respond?

A chain that stops at a consistent point usually indicates a physical break, a failed pass-through at a node/decoder, or a topology issue where a branch or splice is disrupting the data path. The most reliable approach is to isolate the run from the last responding pixel forward until the failure reproduces, then inspect that exact connector, splice, or fixture for continuity, seating, and environmental damage.

Can voltage drop cause some DMX512 facade pixel lights to stop responding?

Yes, and it’s common on low-voltage facade systems. The power supply can read normal at the source while the far-end voltage sags under bright content, causing decoders to reset or behave unpredictably. Measure voltage at the farthest failing point while running full-bright content; if the number drops significantly, correct the power distribution strategy rather than chasing DMX settings.

Why do some facade pixel lights stop responding after rain?

Rain-triggered failures typically come from connectors or splices that are not fully sealed, not fully seated, or mechanically stressed in a way that creates a water path. Moisture can raise resistance, lower voltage at the load, and cause intermittent opens that look like a data fault. Inspect the first non-responding point for corrosion, water marks, and strain, and correct routing and sealing so the issue doesn’t return with the next storm.

How do I tell if it’s a DMX signal problem or a power problem when some pixels aren’t responding?

Look at the symptom under load and test at the failing point, not at the cabinet. If the pixels are dark or reset during bright scenes, power drop is a strong suspect. If power is stable at the failing point but control is missing or erratic, then focus on DMX mode/addressing and the physical data chain. In many facade cases, the right answer is both: marginal power makes the system more sensitive to marginal data.