The need for groundbreaking display solutions has grown significantly recently. Flexible Transparent LED Film has become a major innovation in many sectors. These modern displays blend see-through quality, bendable form, and intense illumination to produce eye-catching results. They are well-suited for uses from building exteriors to store displays. This technology relies on advanced techniques. These methods ensure the creation of high reliable, adaptable films. In this blog, we look at the complex steps involved in making Flexible Transparent LED Film. We also explore its transformative uses. We aim to provide knowledge for companies, creators, and tech fans wanting to use this technology.

Understanding Flexible Transparent LED Film

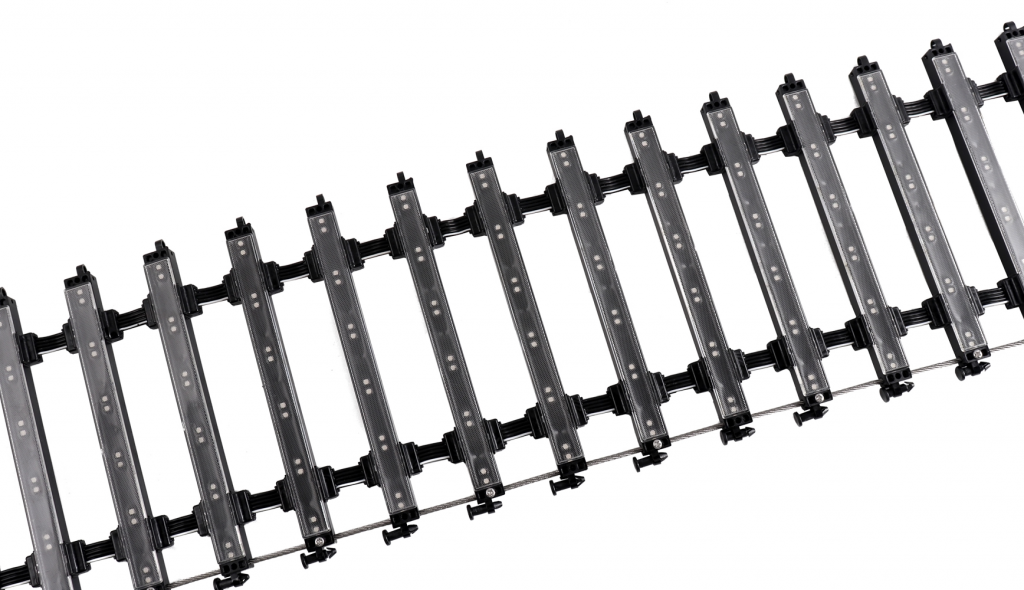

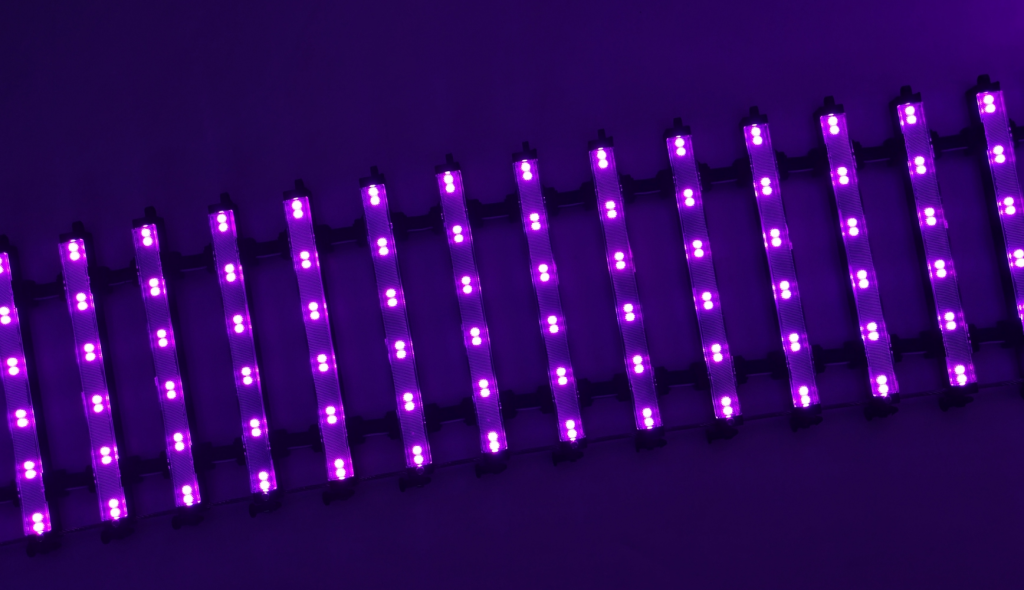

Flexible Transparent LED Film is a revolutionary display method. It embeds LED units into a slender, see-through, pliable base material. Unlike older LED screens, these films keep high see-through quality (up to 95%). This lets them fit smoothly into glass surfaces like windows or walls. They don’t block daylight or the view outside. This makes them perfect for situations where looks and usefulness must work together.

Key Features of Flexible Transparent LED Film

- High See-Through Quality:Reaches up to 95% transparency. This means very little blocking of light or sight.

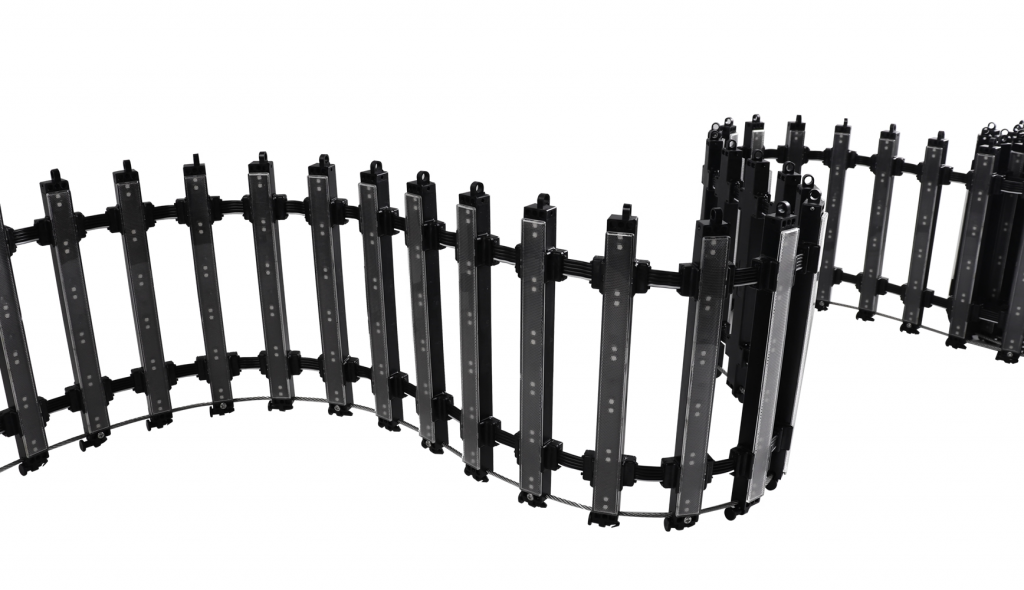

- Bendable Form:Can be curved or shaped to match uneven surfaces. This allows imaginative setups.

- Extremely Slim Build:Usually under 2mm thick. This makes it light and simple to install.

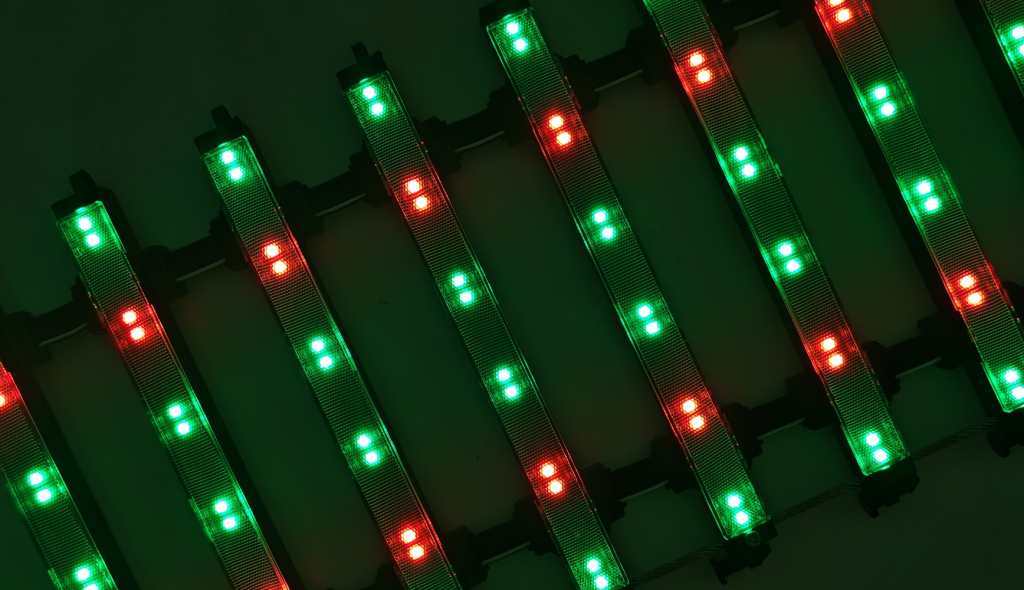

- Intense Illumination:Can achieve up to 6000 cd/m². This ensures bright images even in sunny conditions.

- Tailor-Made Options:Can be trimmed or formed to fit particular project needs.

These qualities make Flexible Transparent LED Film a favored pick for contemporary building designs, shop displays, and interactive exhibits.

Advanced Manufacturing Techniques for Flexible Transparent LED Film

Producing Flexible Transparent LED Film demands exactness, new ideas, and strict quality rules. Below, we examine the sophisticated methods that allow the making of these modern displays.

Mini Encapsulation Technology

Mini Encapsulation is a vital method. This step involves placing tiny LED chips into a see-through base material using sophisticated encapsulation approaches. The outcome is a small, long-lasting, highly transparent display unit.

- Distributed Micro-Hole Heat Dissipation:This special method guarantees effective heat control. It stops overheating and lengthens the working life of the LEDs.

- High Color Accuracy:Optical prism technology improves color display. It gives rich and precise pictures.

PVD Plating Crystal Process

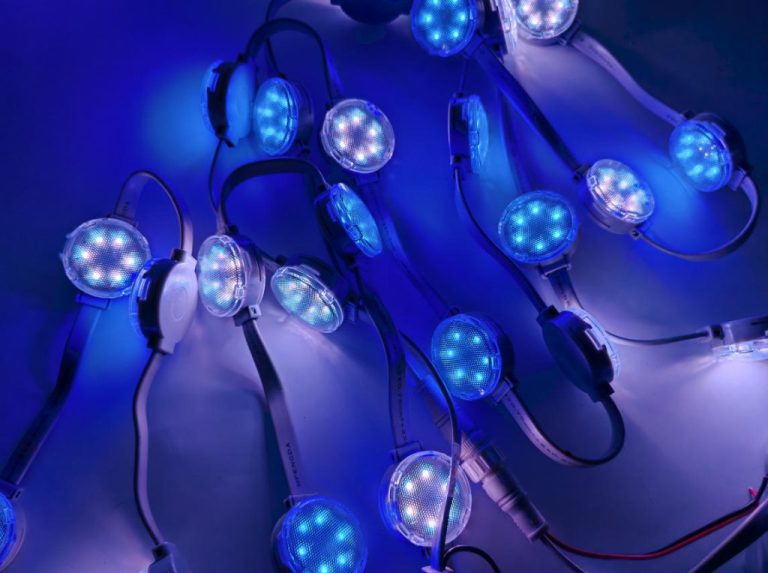

The Physical Vapor Deposition (PVD) plating crystal method is another foundation of production. This method deposits a tiny metal grid onto a clear crystal film. It creates a conductive layer that powers the LEDs while keeping transparency.

- Micro-Metal Grid:Achieves nearly 95% see-through quality. It uses a fine grid pattern that reduces light blocking.

- Longevity:The PVD method increases the film’s strength against outside factors. These include UV light and physical pressure.

Multi-Directional Signal Backup

For guaranteed dependability, sophisticated methods include multi-directional signal backup chips. These chips provide backup paths. This ensures constant working even if one signal route fails. This is a big step up from older breakpoint systems. It offers:

- μA-Level Static Power Usage:Very low power consumption improves energy saving.

- Self-Checking Functions:The system runs automatic checks when turned on. This prevents problems like flickering or staying constantly on.

Flexible Base Material Integration

Using a pliable, see-through base material is central to the film’s adaptability. The material, often a thin polymer or crystal film, is designed to be lightweight, strong, and highly transparent. The joining process involves:

- Exact LED Positioning:LEDs are carefully placed on the material. This ensures even brightness and see-through quality.

- Adhesive Attachment:The film is made to stick right onto glass surfaces. It doesn’t need complicated frames. This makes putting it up easier.

Comparing Core Methods

| ميزة | Manufacturing Technique | Complexity | Key Benefit | Reliability | Application Impact |

| Heat Control | Mini Encapsulation | عالي | Efficient heat dissipation | عالي | Extends LED life, keeps performance |

| الشفافية | PVD Plating Crystal | عالي | High transparency (95%) | عالي | Improves looks in glass setups |

| Operation | Multi-Directional Signal Backup | Medium | Reliable operation | Very High | Lowers downtime, cuts upkeep costs |

| تثبيت | Flexible Substrate Integration | قليل | Easy installation | عالي | Allows varied, creative uses |

Applications of Flexible Transparent LED Film

The adaptability of Flexible Transparent LED Film creates many possibilities. It changes how businesses and creators handle visual communication. Below are some of the most impactful uses.

Building Glass Exteriors

These films are often used in glass curtain walls of modern structures. Examples include company offices, shopping centers, and hotels. These films turn still glass into lively digital screens. They show ads, animations, or brand messages. They do this without harming the building’s appearance.

- City Landmarks:Big setups on tall buildings create famous visual shows.

- Energy Saving:The high see-through quality lets daylight in. This cuts the need for electric lights.

Shop and Business Displays

Retail settings like shop fronts, jewelry stores, and car showrooms gain from the sleek, modern appeal. These displays can show promotions, product details, or interactive content directly on glass windows.

- Better Customer Involvement:Bright images grab attention and bring in visitors.

- Custom Designs:The films can be made to fit specific window sizes or shapes.

Transportation Centers

Airports, train stations, and subway systems use these films for digital signs, directions, and ads. Their light weight and pliable nature make them perfect for large, curved glass areas.

- Current Information:Displays can show timetables, news, or ads.

- Aesthetic Blending:The see-through design fits perfectly with modern facilities.

Interactive and Creative Exhibits

The pliability and interactivity make them ideal for artistic and experience-based exhibits. Examples include museums, galleries, or event spaces.

- Sensor Addition:Films can connect with sensors for touch, light, or temperature reactions.

- Virtual Reality Pairing:Works well with VR and AR setups. This deepens immersive experiences.

XinHe Lighting Optoelectronics: A Leading Supplier

Shenzhen XinHe Lighting Optoelectronics Co., Ltd. started in 2004. It is a trusted name in the LED field. It specializes in creating and applying Flexible Transparent LED Film under its well-known “Bean” brand. With over 20 years of experience, XinHe has pioneered new ideas like the crystal truss screen. This shows the company’s focus on quality and modern technology. Certified under ISO14001:2015 and ISO9001:2015, XinHe ensures top standards in making things and caring for the environment. Their films are known for extremely thin builds, high see-through quality, and simple installation. They are made for various uses, from glass curtain walls to shop displays. With a global reach and over 80 patents, XinHe continues to lead the industry. It focuses on new ideas, quality, and customer happiness.

خاتمة

The rise of Flexible Transparent LED Film is a big step forward in display technology. It is driven by sophisticated methods that focus on see-through quality, pliability, and strength. From building exteriors to interactive shop displays, these films offer unmatched versatility and visual charm. By using modern steps like Mini Encapsulation, PVD Plating, and multi-directional signal backup, makers like XinHe Lighting Optoelectronics deliver goods that meet modern demands. As businesses and creators keep looking for new visual solutions, these films will play a key part in shaping the future of digital displays.

FAQs

What are the main advantages of using this film in shops?

Flexible Transparent LED Films offer high see-through quality (up to 95%). This lets natural light pass while showing bright content. Their pliability allows fitting on curved or unusual surfaces. Their extremely thin build (under 2mm) gives a sleek, modern appearance. In shops, these films boost customer interest through lively ads and promotions. They fit smoothly with glass shop fronts.

How do the manufacturing methods make the films last longer?

Sophisticated methods like Mini Encapsulation with micro-hole heat control and PVD Plating Crystal steps improve longevity. They do this by better heat handling and resistance to outside factors like UV light. Multi-directional signal backup chips ensure dependable working. This lowers the chance of failures and extends the film’s life.

Can these films be tailored for specific project needs?

Yes, they are highly adaptable. They can be cut or shaped to match exact sizes and surfaces. This makes them great for unique setups. Furthermore, the sophisticated methods allow for custom brightness levels, pixel arrangements, and sensor additions to meet different project requirements.

What kinds of uses are best for this film?

Good uses include glass curtain walls in structures, shop fronts, transport hubs, and interactive exhibits. They are ideal for situations needing high see-through quality, pliability, and bright displays. Examples are city landmarks, business displays, and creative installations.

How does installing this film work?

Putting it up is straightforward. It doesn’t need complicated frames. The extremely thin film sticks right onto glass surfaces using adhesive. This makes applying and removing it simple. This sophisticated method lowers installation costs and time. It enables quick setup for different applications.