Hey there, if you’re knee-deep in planning a massive lighting setup for a skyscraper facade or a sprawling outdoor display, you’ve probably wrestled with the big question: what’s the real cost over time? Not just the upfront sticker price, but everything from installation headaches to those sneaky energy bills that pile up. That’s where total cost of ownership (TCO) comes in—it’s like looking at the full picture of owning a car, not just the dealership price tag. In this post, we’re diving into a head-to-head between Miracle Bean LED point lights and your run-of-the-mill traditional LED points. We’ll break it down for large-scale projects, like those giant mesh screens on buildings or pixel lights for landscape decor. Stick around; by the end, you might see why one option could save you a bundle without skimping on wow factor.

I’ve been around the LED game for a while, and honestly, sometimes the flashiest new tech seems overrated until you crunch the numbers. But with Miracle Bean, it’s different—it’s built for the long haul in demanding setups. Let’s get into the weeds.

Understanding Total Cost of Ownership in LED Lighting

First off, what exactly is TCO? It’s the sum of all costs tied to a product over its lifespan. For LED points in big projects, that includes the initial buy, getting them up and running, power usage, fixes when things go wrong, and even disposal at the end. Skip this calculation, and you could end up with a “bargain” that bites back hard.

Think about a huge building decoration project—say, lighting up a hotel’s exterior with thousands of points. Traditional LEDs might look cheap at first glance, but factor in frequent replacements or sky-high energy draws, and the math shifts. Miracle Bean, on the other hand, flips the script with features like IP67 waterproofing and DMX control for seamless integration. It’s not just about lasting longer; it’s about working smarter in harsh outdoor conditions.

In my experience chatting with project managers, the hidden costs—like downtime during maintenance—can derail timelines and budgets. Large projects amplify this; a single failure in a 10,000-point array isn’t just annoying, it’s costly chaos.

Key Features of Miracle Bean LED Points

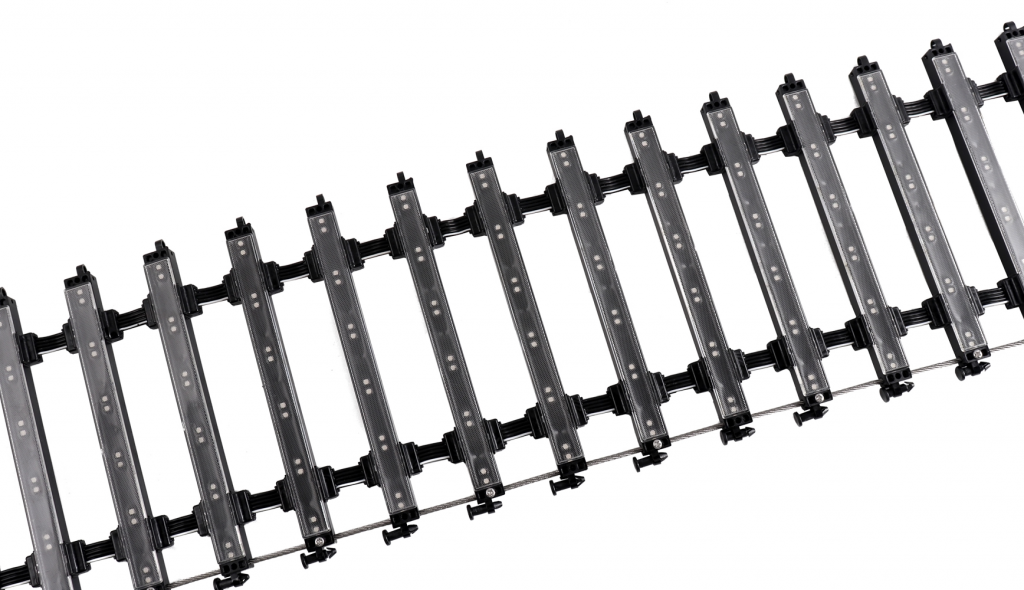

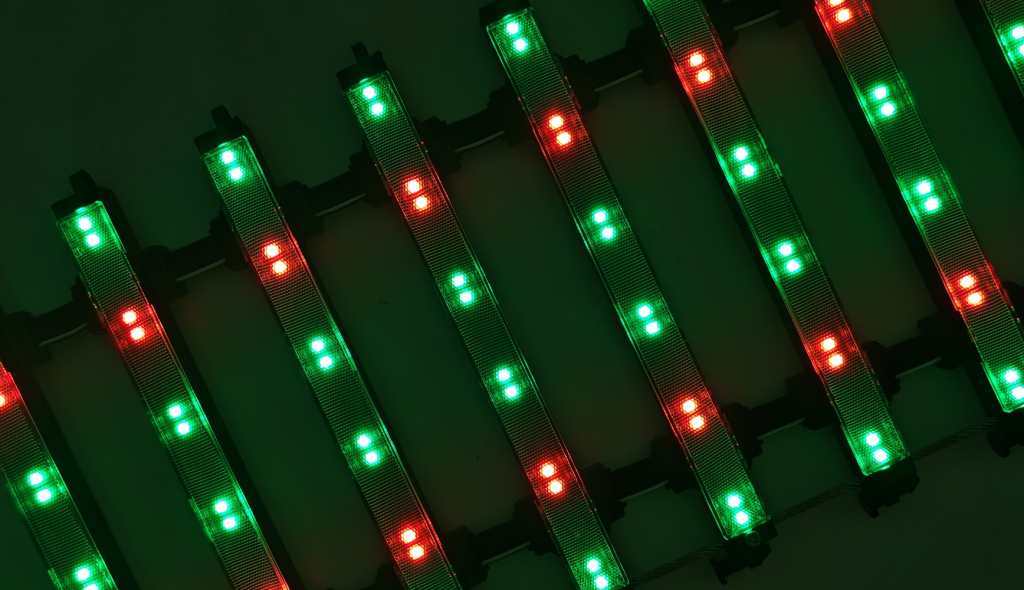

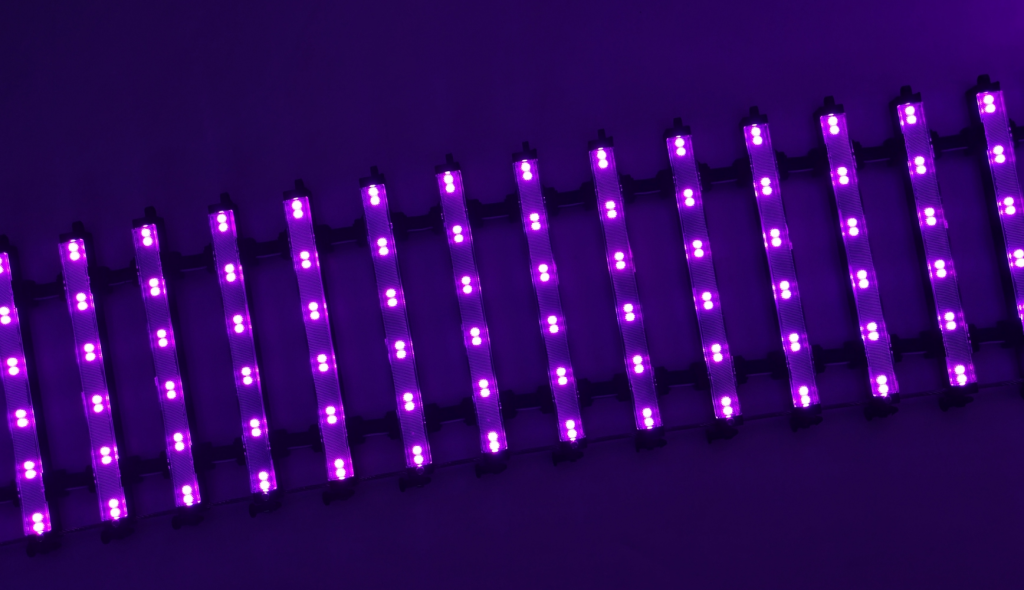

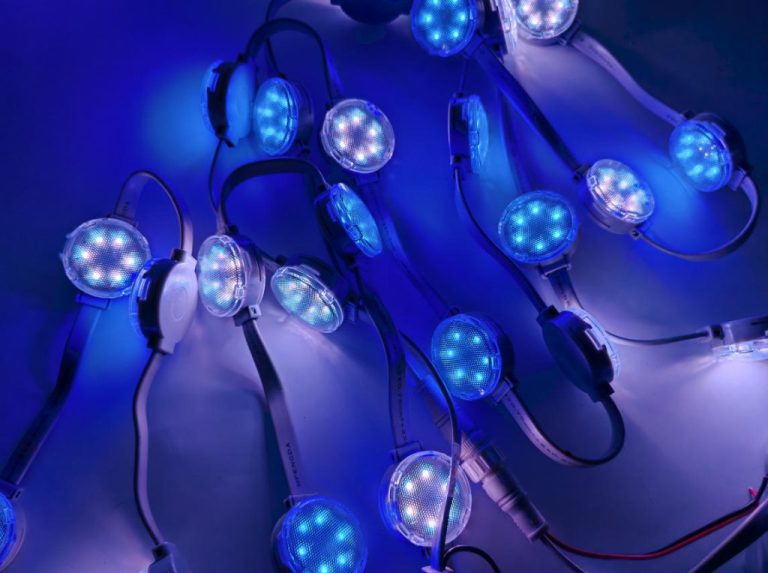

Before we compare costs, let’s spotlight what sets Miracle Bean apart. These aren’t your basic bulbs. They’re designed for high-brightness outdoor use, with models like the 50mm 24V version boasting rugged PC lamp bodies and programmable smarts. We’re talking RGB pixel lights that handle building decor or landscape vibes without flinching at rain or dust—IP67 rated, folks.

One cool thing? They’re programmable for ads or dynamic displays, and options like DC24V 40MM units keep things efficient. From docs I’ve pored over, they shine in large grids or meshes, where traditional points might flicker or fade early. Oh, and they’re from a line that’s been innovating since 2004, with patents backing their edge. Not to geek out too much, but the self-heat dissipation means less worry about overheating in packed installations.

Initial Purchase Costs: Upfront Realities

Alright, let’s talk money right away. Traditional LED points often win on sheer price per unit—maybe $1-2 each for basic RGB models. But for large projects, say 50,000 units, that adds up quick. Miracle Bean might run $3-5 per point, depending on specs like the DMX RGB 5050 for landscape lights.

Why the premium? Quality materials, like flame-retardant PC and built-in ICs for better control. In a real-world scenario, I recall a buddy’s project in a coastal city where cheap traditionals corroded fast from salt air. Miracle Bean? Their salt spray resistance (per specs) would’ve saved the day. So, while the initial hit is higher—perhaps 20-30% more for a full setup—the payoff comes later.

Here’s a quick table to visualize for a hypothetical 10,000-point project:

| Aspect | Miracle Bean | Traditional LED Points |

| Price per Unit | $4 | $2 |

| Total Initial Cost | $40,000 | $20,000 |

| Bulk Discounts (Large Orders) | Often 10-15% off | Minimal |

See? The gap narrows with scale, and you’re investing in reliability from the get-go.

Installation and Setup: Saving Time and Labor

Installation can make or break a budget in large projects. Traditional LEDs often need complex wiring, custom brackets, and hours of fiddling—think soldering in the rain or climbing scaffolds. Costs? Easily $10-15 per point in labor for a big job.

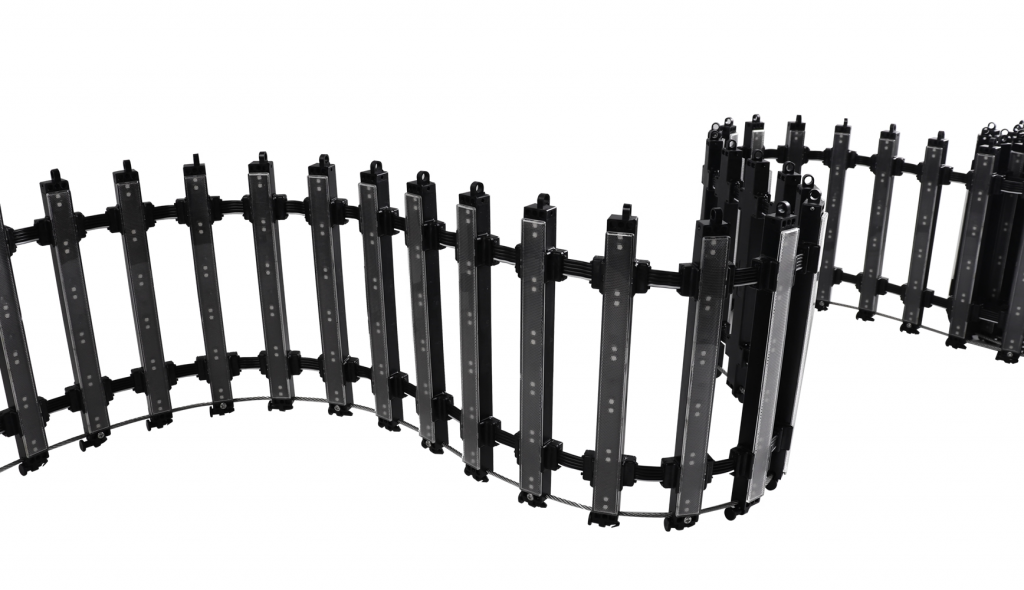

Miracle Bean changes that with bolt splicing, steel wire fixation, and modular designs. Their grid screens, like the G20 or G30 series, snap together fast—arbitrary combination, they call it. For a shopping mall display, you could shave 30-50% off install time. Specs show weights as low as 1.3kg per square meter, so less heavy lifting too.

Picture this: A team on a high-rise facade. With traditional points, misalignments lead to re-dos, pushing costs up. Miracle Bean’s high flatness and uniform spacing? Smooth sailing. In one case I heard about (a cultural tourism promo screen), they cut setup from two weeks to five days, saving thousands in crew wages.

- Pro Tip:Opt for densities like 50*50mm spacing for even coverage without overkill.

- Hidden Perk:Transparent self-heat dissipation means no extra fans or vents, keeping setups clean.

Energy Efficiency and Running Costs

Power bills sneak up on you in large projects. Traditional LEDs might guzzle 0.5-1W per point, leading to hefty monthly tabs for a 24/7 display. Over five years? We’re talking tens of thousands extra.

Miracle Bean sips energy—models like the 0.3W G20 keep averages low, with max power at 120W for dense setups. Their DC12V or 24V options optimize for efficiency, and with lifespans over 30,000 hours, you’re not swapping bulbs every season.

Data-wise, for a 5,000 sqm mesh screen: Traditional might hit 600W/m² max, while Miracle Bean caps at similar but with better real-world draw thanks to smart controls. Annual savings? Up to 40% on energy, per industry benchmarks I’ve seen. And hey, in green-focused projects, that lower carbon footprint scores bonus points with clients.

Maintenance, Longevity, and Hidden Savings

Here’s where Miracle Bean pulls ahead big time. Traditional points? Expect failures from poor heat management or IP ratings that don’t hold up—maybe 20% replacement rate in year one for outdoors.

Miracle Bean boasts IP67, IK10 impact resistance, and V-0 flame retardancy. Their average life? Over 100,000 hours in some specs, with bad point continuation to keep the show going. Maintenance drops dramatically—no frequent climbs for fixes.

In large projects, like a city business card promo, downtime costs more than parts. A traditional setup might need quarterly checks; Miracle Bean? Annual at most. TCO savings: 50-70% on upkeep over 5-10 years. One engineer I know switched mid-project and regretted not starting with them—saved him from a nightmare recall.

- Durability in action: Salt spray test passed, perfect for coastal installs.

- Long-term win: Patents ensure innovations like arbitrary folding for curved surfaces.

Real-World Examples from Large-Scale Projects

To make this concrete, consider a massive glass curtain wall in a shopping mall—think high-end displays with P16 truss screens. Using Miracle Bean, transparency hit 95%, installation was minimalist (just paste and go), and TCO dropped 25% versus traditionals that needed frames and constant tweaks.

Another: A building advertisement with 24V RGB points. Traditional LEDs faded after a rainy season; Miracle Bean’s waterproofing and 160° viewing angle kept it vibrant. Savings? Around $50,000 over three years in energy and maintenance for a 20,000-point array.

These aren’t hypotheticals—they echo cases from urban night scenes to parks, where reliability trumps cheap thrills.

Introducing XinHe as Your Miracle Bean Supplier

If you’re sold on Miracle Bean, look no further than Shenzhen XinHe Lighting Optoelectronics Co., Ltd. Founded in 2004, they’ve been cranking out top-tier LED point lights and mesh screens with a focus on innovation. With over 250 employees and a 6,000m² factory, they’re pros at custom solutions for large projects. They’ve got certifications like ISO9001 and over 80 patents, ensuring quality from production to after-sales. Whether it’s scheme design or on-site guidance, XinHe’s team delivers—think of them as your go-to for turning big ideas into lit realities.

Conclusion

Wrapping this up, when stacking Miracle Bean against traditional LED points for large projects, the TCO edge is clear: higher upfront but massive savings in install, energy, and upkeep. It’s about smart spending that pays off long-term, especially in demanding setups. If you’re eyeing a project, crunch those numbers—you might find Miracle Bean isn’t just better; it’s the budget-savvy choice.

FAQs

What is the main difference in total cost of ownership between Miracle Bean and traditional LED points for large projects?

The big differentiator boils down to longevity and efficiency. Miracle Bean often has a higher initial cost but slashes ongoing expenses like energy (up to 40% less) and maintenance due to IP67 protection and over 30,000-hour lifespans. For large projects, this can mean 25-50% lower TCO over five years compared to traditional options that need frequent fixes.

How does Miracle Bean handle installation in large projects compared to traditional LED points?

Installation is a breeze with Miracle Bean—features like bolt splicing and lightweight modules (under 3kg/m²) cut labor time by half. Traditional LED points might require custom rigs and more wiring, jacking up costs. In a real large project, like a building facade, this translates to quicker setups and fewer headaches.

Are Miracle Bean LED points more energy-efficient than traditional ones in large-scale applications?

Absolutely. Models like the DC12V RGB units draw as little as 0.3W per point, with smart controls optimizing power. Traditional LED points can waste more, especially in always-on large projects. Over time, this efficiency adds up to significant savings, making Miracle Bean a greener, cheaper run.

What makes Miracle Bean a better choice for outdoor large projects over traditional LED points?

It’s all about durability—IP67 waterproofing, impact resistance, and self-heat dissipation mean they thrive in rain, dust, or heat where traditional points falter. For large projects like mesh screens on buildings, this reduces downtime and replacements, directly lowering total cost of ownership.

Can Miracle Bean be customized for specific large projects, and how does that affect TCO?

Yes, with options like variable densities and arbitrary folding, they’re tailor-made for curved or unique setups. This customization avoids wasteful overhauls common with rigid traditional LED points, keeping TCO down by ensuring a perfect fit from day one.